EPC Printing and Encoding

Electronic Product Code (EPC) Printing & Compliance Made Easy with PortalTrack®.

PortalTrack’s EPC-compliance solutions have been deployed globally by some of the world’s largest manufacturers and most recognizable brand owners. Designed on a scalable platform and utilizing cloud based architecture, PortalTrack will ensure that you meet all of your Electronic Product Code tagging requirements, including compliance with industry and legislative guidelines on consumer protection, consumer privacy and security.

Ensuring EPC Verification & Quality Assurance with PortalTrack.

MSM Solutions built the secure, scalable PortalTrack platform around industry-standard EPC guidelines and best practices for quality validation, delivering peace of mind and exceptional efficiency across many different applications.

PortalTrack complies with GS1 industry standards, accepted as the guiding global principal that drives real-time tracking, traceability and supply chain optimization in retail, manufacturing, healthcare, logistics and distribution. GS1 standards help highlight what really matters, providing common language to identify, capture and share data.

PortalTrack’s EPC verification system ensures the quality of printed tickets and labels while also making sure that they meet the requirements of your customers, eliminating costly charge backs. Verification systems can be integrated with in-line conveyor systems or thermal printing systems to trigger alerts when quality standards are not met.

Trusted by major corporations and brands worldwide, PortalTrack has been deployed in mission critical applications with the Department of Defense, leading rfid healthcare providers and global retailers with large distributed enterprises. With a robust verification and quality assurance program, PortalTrack ensures that EPC information is accessible, accurate and easily understood for each and every item throughout the entire supply chain, end-to-end, reducing costs and increasing return on investment.

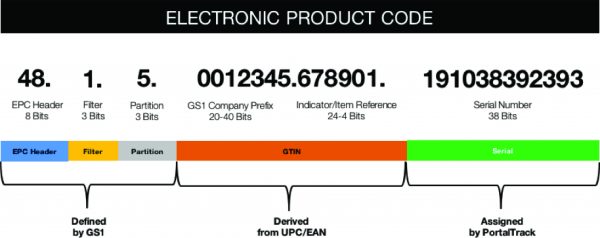

What is an Electronic Product Code?

An Electronic Product Code (EPC) is a universal identifier that gives a unique identity to a specific physical object. The identities assigned to the objects are encoded on an RFID tags and can be used to track almost any object including fixed and mobile assets, documents, reusable transit items, consumer goods or any other physical object.

Where are RFID Tags Printed and Encoded?

An Electronic Product Code (EPC) is a universal identifier that gives a unique identity to a specific physical object. The identities assigned to the objects are encoded on RFID tags and can be used to track almost any object including fixed and mobile assets, documents, reusable transit items, consumer goods or any other physical object.

1

At the Source

Print on demand only the labels you need, when you need them, to avoid excess, obsolete tag inventory and improve management of serialization.

2

In the Store

Customizable print solutions enable fast, easy and cost effective replacement of missing and inaccurate hangtags.

3

At the Distribution Center

Consolidates EPC and barcode data on one label, eliminating the supplemental re-ticketing, to simplify logistics and realize considerable savings in time and money.

4

At the Service Bureau

Save time by having hangtags and labels printed in bulk at our service bureau for fast and responsive deliver to the manufacturing source.

Core Benefits of Using PortalTrack for EPC Printing and Encoding of RFID Tags

PortalTrack delivers the power to take complete control over printing and encoding of all of your RFID tags and labels, when and where you want them, for reduced operational costs and maximum efficiency throughout the entire supply chain. A scalable, customizable solution, PortalTrack delivers best total cost of ownership, whether for a single application or an intricate global enterprise solution.

Reduces Operational Costs

Consolidate existing UPC labels into a single RFID label and significantly reduce your labor and material costs.

Real-Time Visibility

Easily see what RFID tags have been printed, where and when they were printed, and who printed them.

Proven ERP, WMS & Proprietary Integration

PortalTrack is a scalable solution with a tailored cost structure that can start with a single application and extend into a global enterprise solution and beyond.

Multi-Chip Vendor EPC Serialization

With PortalTrack you can easily manage tag serial numbers on a global scale allowing you to more efficiently allocate your IT resources.

GS1 Compliant for EPC Item Level Tagging

PortalTrack supports both MCS and managed serialization of EPC tags from the worlds leading RFID tag manufacturers.

Secure EPC Data Management

Designed in compliance with the latest EPC security protocols, PortalTrack software enables real-time data monitoring and analytics while safeguarding information.

Why is EPC Verification and Validation Important?

Ensure Data Integrity

Mislabeled and inaccurate shipments cost brand owners millions of dollars each year in wasted resources and labor costs, and can ultimately lead to unsatisfied customers who don’t receive the items they thought they’d purchased. With EPC data verification you can ensure that all of the correct items are in a specific shipment or package.

Order Process Assurance

With RFID EPC data you can easily control and automate your entire order and replenishment processes to ensure your customers have a positive experience in today’s Omni-channel retail environment. With RFID you can ensure that your current and future customers’ needs are fulfilled.

Gray Market Mitigation

Ensuring that the right products get delivered to the right sales channels is a critical component of protecting the equity of your brand. With EPC data you’ll have be able to understand if your products are flowing through unauthorized channels.

Anti-Counterfeiting

Every year brand owners and retailers lose billions of dollars in revenue to counterfeit good sales. In many cases, the counterfeiters have become so good at what they do that it’s become extremely difficult to distinguish legitimate vs. fake goods with the naked eye. With RFID EPC data, you’ll be able to easily determine what’s real and what isn’t.