Effective inventory management is the backbone of any successful business, ensuring that products are available to meet customer demand while minimizing excess stock and reducing operational costs. As businesses evolve and the complexity of supply chains increases, traditional inventory management methods are proving insufficient. This is where Radio Frequency Identification (RFID) technology comes into play, offering a revolutionary approach to inventory management. In this fourth installment of our series on RFID software, we will delve into the transformative power of RFID for inventory management, building on the foundations laid in previous parts of this series.

Understanding RFID Inventory Management

RFID systems streamline inventory management by automating data capture, allowing for the simultaneous reading of multiple tags without the need for manual scanning. This automation significantly reduces the risk of human error and ensures that inventory data is updated in real time. The real-time visibility provided by RFID allows businesses to track inventory levels more accurately, optimize stock management, and respond quickly to supply chain demands.

In today’s dynamic business environment, the ability to access accurate, up-to-date inventory data is crucial. RFID technology enhances inventory management by offering greater efficiency, reducing manual labor, and enabling businesses to make quicker, data-driven decisions. This leads to improved operational efficiency, reduced costs, and a more responsive supply chain.

How RFID Works in Inventory Management

The RFID system relies on four key components: tags, readers, antennas, and software. The RFID tags, which store essential information about each item, communicate with readers and antennas to capture data. This data is then processed by software, turning it into actionable insights for your business.

The process starts when you tag an inventory item. As the tagged items move through the supply chain or warehouse, RFID readers capture data in real-time, automatically updating inventory levels. This seamless process ensures accurate records, enabling your business to quickly respond to changes in inventory status, reducing the risk of stockouts or overstock situations.

Advantages of RFID in Inventory Management

RFID technology is a game-changer in inventory management, bringing a new level of accuracy and efficiency to the process. By automating data capture, RFID slashes the margin for error and eliminates the headaches of manual inventory counts. With RFID, businesses gain real-time visibility into their inventory, allowing for instant updates that enable smarter decisions about restocking, order fulfillment, and inventory allocation.

This technology doesn’t just make your operations more accurate; it also lightens the load for your team. By reducing the need for manual labor, RFID frees up your staff to focus on more strategic, value-added tasks. Plus, with fewer opportunities for human error, the reliability of your inventory data gets a significant boost.

RFID also gives you tighter control over your inventory, with detailed tracking that helps prevent losses due to theft, misplacement, or administrative errors. And if your business already uses ERP or WMS systems, RFID seamlessly integrates, enhancing those systems with real-time tracking and management capabilities. This integration not only ensures a smooth transition but also maximizes the value of your existing systems, driving better efficiency and ultimately, better business results.

RFID Inventory Management Software

When selecting RFID inventory management, consider features such as real-time tracking, integration capabilities, scalability, and customizable reporting tools. These features ensure that the software meets your business’s specific needs and can grow with your operations.

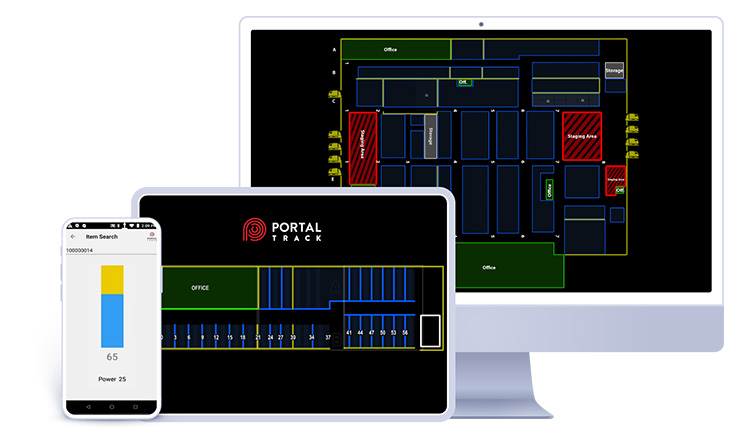

MSM Solutions’ PortalTrack RFID software stands out as a customizable, scalable platform that integrates with existing ERP and WMS systems. It offers real-time data visibility, automated reporting, and event monitoring, providing businesses with the tools they need to manage inventory effectively.

RFID Inventory Use Cases

- Enhanced Workflow Efficiency: By integrating RFID systems with existing inventory management processes, businesses can streamline workflows. RFID tags and readers facilitate faster throughput of goods, minimizing manual intervention and increasing operational efficiency.

- Pallet-Level and Zone-Based Tracking: RFID enables precise tracking of pallets and products within large facilities, such as warehouses or manufacturing plants. The technology can be used to divide areas into zones, providing detailed visibility of inventory movement and ensuring that items are quickly located and retrieved.

- Error Reduction in Shipping and Receiving: RFID systems help validate orders by automatically scanning and verifying items during packing and receiving processes. This reduces errors, prevents mis-shipments, and ensures that the correct products are delivered, enhancing overall accuracy in the supply chain.

- Mobile Tracking and Reporting: Equipping workers with mobile RFID readers and tablets enhances inventory management by allowing them to assign specific locations to pallets or items within a facility. This mobile capability simplifies the tracking process and reduces the time spent searching for misplaced inventory.

Challenges and Solutions in RFID Inventory Management

Implementing RFID in inventory management offers substantial benefits, but it’s not without its challenges. High initial costs, integration complexities, and the need for staff training are common hurdles businesses may face when adopting this technology.

To address these challenges, it’s crucial to approach RFID implementation strategically. Opt for scalable solutions that can grow with your business, ensuring that the technology adapts to your needs over time. Integration doesn’t have to be overwhelming; start with a phased approach, gradually incorporating RFID into your existing systems to minimize disruption and ease the transition. Thorough training programs are essential to ensure that your team is comfortable with the new technology, helping to prevent operational hiccups and maximize the effectiveness of your RFID system.

By taking these steps, businesses can successfully navigate the initial challenges and unlock the full potential of RFID inventory management.

Future Trends in RFID Inventory Management

The future of RFID in inventory management is bright, driven by innovations like IoT integration, blockchain for secure tracking, and AI for predictive analytics. These emerging technologies will not only enhance RFID’s capabilities but also open new avenues for efficiency and accuracy. As RFID evolves, it’s poised to become an even more indispensable tool, offering businesses deeper insights and more robust control over their inventory than ever before.

Choosing the Right RFID Solution for Your Business

Selecting the right RFID solution is crucial for comprehensive inventory management. It’s important to choose a vendor that can provide a complete solution, from hardware to software and everything in between. MSM Solutions is unique in this regard, offering fully encoded and printed RFID tags, top-of-the-line RFID hardware from the best providers in the industry, expert RFID consulting and installation services, as well as their advanced PortalTrack RFID software. This end-to-end capability ensures seamless integration and operation of your RFID system, enhancing asset tracking, inventory accuracy, and overall operational efficiency.

RFID technology delivers inventory management solutions for more than just retail and apparel. Healthcare, manufacturing, automotive, and distribution have all seen RFID enhance operational efficiencies. Embrace RFID technology with MSM Solutions, and step into a future where every asset is just a scan away from revealing its comprehensive digital identity. Deployed globally, many of the world’s leading and most recognizable brands trust MSM Solutions and PortalTrack RFID software to monitor millions of events around the world every single day for them.

MSM Solutions recognizes that every business is different. Contact MSM Solutions today for a free consultation and we will provide you with straight answers on feasibility and cost.