The global food supply chain is undergoing a traceability revolution, driven by demands for greater visibility, enhanced safety, and regulatory compliance. At the forefront of this change are major retailers setting new standards and federal regulators pushing supply chains toward a new era of digital tracking.

For businesses involved in food manufacturing, distribution, and retail, the integration of RFID (Radio Frequency Identification) technology is no longer optional – it’s essential.

Walmart, a long-time driver of RFID adoption, is once again leading the charge. The retailer is expanding its RFID mandates into complex fresh food categories, including meat, bakery, and deli. Simultaneously, the FDA is driving new requirements under the Food Safety Modernization Act (FSMA) that require specific record-keeping for certain foods with its “Food Traceability Rule,” a sweeping regulation designed to prevent foodborne illness necessitating solutions like RFID.

Solving the Critical Challenges of Food Traceability

For years, the food industry has struggled with two major issues: food waste and food safety.

- Food Safety & Recalls: When an outbreak (like E. coli in romaine lettuce) occurs, investigators face a race against time. The inability to quickly and precisely trace a contaminated product back to its source leads to massive, costly recalls, erodes consumer trust, and, most importantly, endangers public health. The FDA’s new traceability rule (with a compliance date of 2028) was created specifically to solve this, requiring detailed record-keeping for high-risk foods.

- Food Waste & Spoilage: In the fresh food aisles, the clock is always ticking. Retailers like Walmart are tackling their goal of halving food waste by 2030. Manually tracking expiration dates on thousands of items is inefficient and prone to error.

The Benefits: From Farm-to-Fork Efficiency

Adopting RFID technology creates a ripple effect of benefits for retailers, suppliers, and consumers alike.

- Drastically Reduced Food Waste: By tagging individual items or cartons, retailers gain real-time data on product freshness. Digital use-by dates allow associates to “first-in, first-out” with precision, identifying items needing to be marked down for quick sale instead of being thrown away.

- Improved Inventory Management: RFID provides unparalleled inventory accuracy. Instead of scanning individual barcodes, an employee can scan an entire case or pallet in seconds, knowing exactly what’s in stock, what’s expiring, and where it is.

- Enhanced Product Freshness: Consumers get access to fresher, safer food because stock rotation is optimized, and any recall can be executed with surgical precision, removing only the affected items.

- Operational Efficiency: The technology significantly cuts down on manual labor. This frees up store associates to spend less time scanning inventory and more time helping customers.

How RFID Works (and How MSM Solutions Helps)

- RFID sensor tags that are specifically engineered to meet the demands of the food industry. MSM solutions have RFID tags designed to work reliably in the cold, damp, and fast-moving environments of the fresh food supply chain, ensuring you have accurate data when you need it most.

- Control with PortalTrack™: Our proprietary software, PortalTrack™, is a customizable solution trusted by leading brands worldwide. PortalTrack harnesses the power of RFID technology to identify, count, track, and manage millions of objects every day. It provides the real-time visibility and intelligent analytical reporting required to make timely decisions, eliminating wasted labor searching for items and preventing shipment delays.

- Hardware and Media Expertise: We are experts in implementing user-friendly technologies, including mobile computers, barcode scanners, RFID readers, and thermal printers. We partner with industry leaders to bring you the most reliable and durable devices available, offering specialized services such as EPC printing and encoding to ensure compliance with industry and legislative guidelines.

- Seamless Integration: MSM Solutions provides a turnkey solution that includes on-site hardware and software integration. Our in-house engineering team can integrate PortalTrack into your existing business operations, connecting to WMS, ERP, and proprietary systems.

How to Get Started with the FDA Traceability Rule

Complying with the FDA’s Food Traceability Rule (FSMA 204) can feel complex, but it begins with a few foundational steps. Here’s a simple “at-a-glance” guide to getting started:

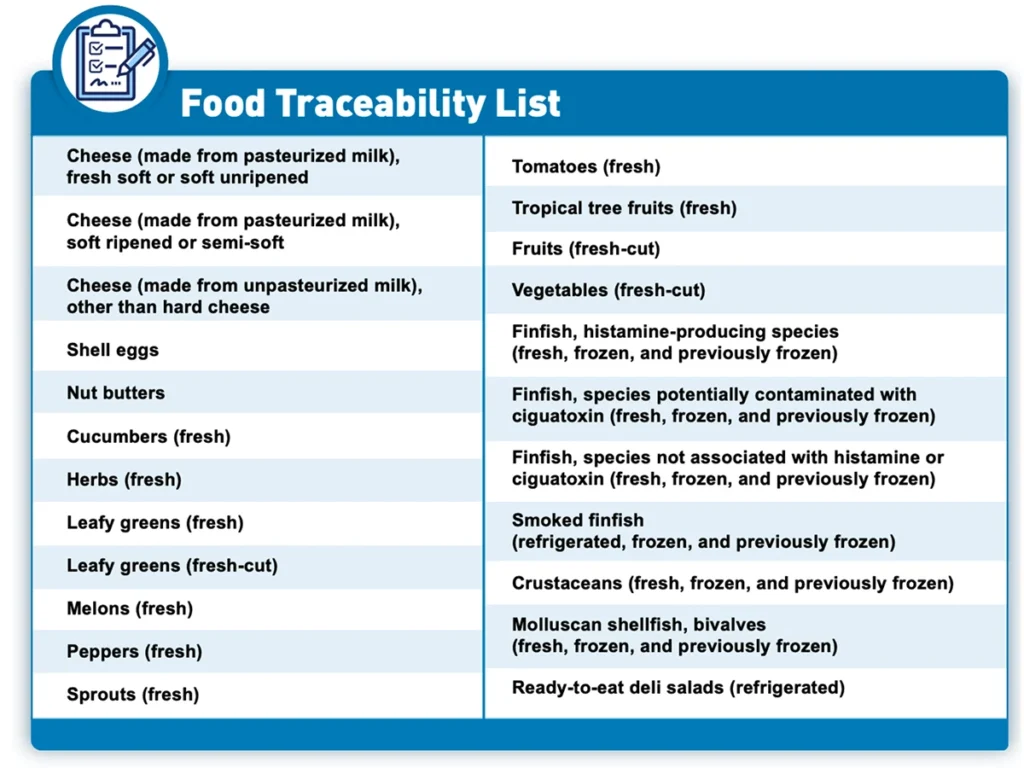

- Know Your List: First, determine if you manufacture, process, pack, or hold any foods on the FDA’s Food Traceability List (FTL). This list includes items like leafy greens, fresh-cut fruits and vegetables, shell eggs, nut butters, and certain fresh fish.

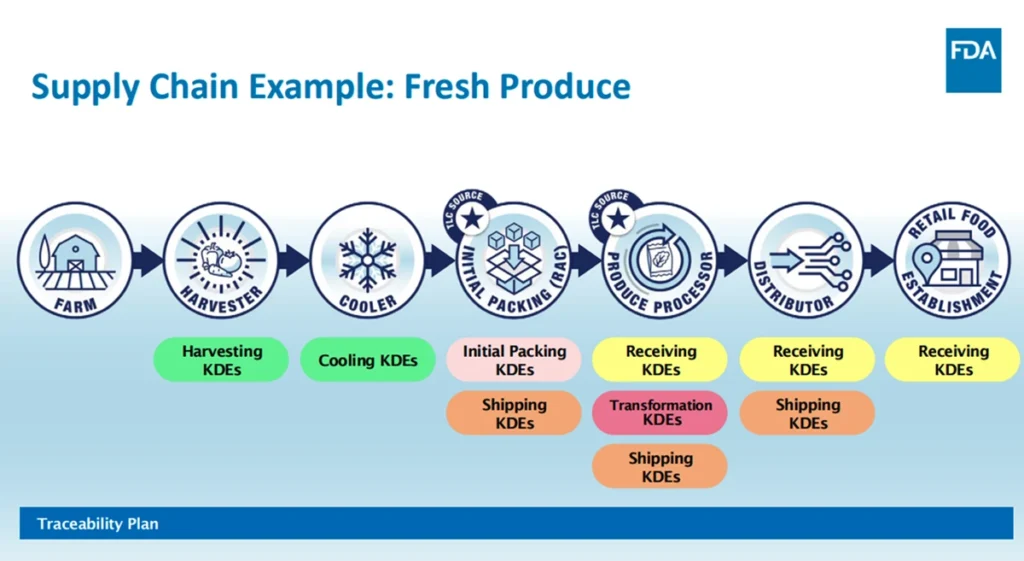

- Identify Your Events: Understand which Critical Tracking Events (CTEs) your business performs. These are the key steps in the supply chain, such as harvesting, cooling, initial packing, shipping, and receiving.

- Capture Your Data: For each CTE you perform, the FDA requires you to keep specific Key Data Elements (KDEs). This is the “who, what, where, and when” of your product’s journey, which must be linked to a Traceability Lot Code (TLC).

- Create a Traceability Plan: The rule requires a formal, written plan that describes your traceability procedures, how you identify FTL foods, how you assign lot codes (if applicable), and a point of contact.

- Talk to Your Partners: Communicate with your suppliers and customers to determine how this essential data will be shared and maintained throughout the supply chain.

This is where technology becomes essential. A digital system, supported by RFID tags and labels from MSM Solutions, is the most effective way to capture, manage, and share these extensive data requirements accurately and efficiently.

Get Ready for Complete Visibility?

The shift toward mandated item-level traceability is happening now. By partnering with MSM Solutions, you can leverage our expertise in RFID and barcode technologies to secure real-time supply chain data and move products faster and more accurately.

Contact MSM Solutions today to discuss how our customized, integrated solutions can meet your food traceability needs. We enable you to Identify. Track. Count. Manage.