Fixed Industrial Scanning: Why Speed and Accuracy Matter in Manufacturing

What if you could boost throughput, improve quality, and eliminate barcode errors without adding resource or slowing down production?

Fixed industrial scanning provides a reliable, automated method of capturing the critical data that keeps production and distribution moving. For manufacturers, warehouses, and logistics operations under pressure to improve efficiency and accuracy, fixed industrial scanners deliver consistent, always-on performance without adding complexity to the workflow.

By replacing manual barcode scanning with high-speed, hands-free automation, fixed scanners help you maintain accuracy, streamline workflows, and make better decisions in real time.

Let’s explore how this technology works, where it delivers the biggest impact, and why the right integration partner is the key to getting it right.

From Manual to Automated: What Is Fixed Barcode Scanning?

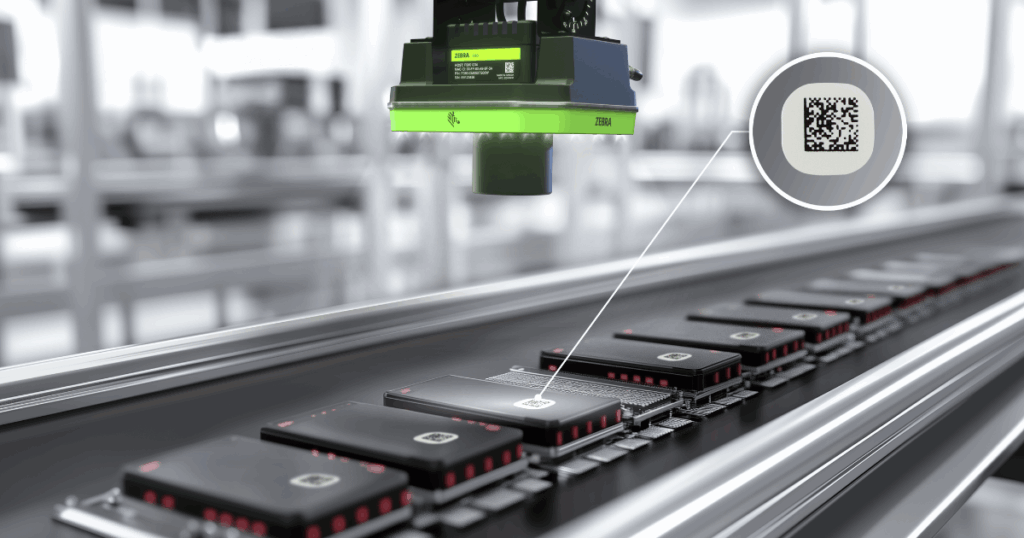

Unlike handheld scanners that require an operator to trigger every read, fixed barcode scanners are permanently mounted over a conveyor, assembly line, or packaging station. They automatically read 1D and 2D barcodes at high speed — even if the labels are damaged, dirty, poorly printed, or in motion.

With a solution like Zebra’s FS and GS Series Fixed Industrial Scanners, this means:

- No more missed scans that cause shipping errors or quality issues.

- Consistent throughput without stopping production for manual checks.

- Seamless data capture that integrates with MES, ERP, and WMS platforms.

Typical applications include:

- Manufacturing – Tracking components through each production stage for traceability and quality control.

- Warehousing – Verifying orders, scanning pallets and cartons, and locating inventory.

- Logistics – Automating shipping/receiving validation, cross-docking accuracy, and load confirmation.

- Packaging – Ensuring the right labels, barcodes, and product information are in place before items leave your facility.

Does Fixed Scanning Outperform Handheld Scanning Operation?

In a high-volume environment, manual barcode scanning is prone to human error, inconsistent speed, and operator fatigue. Even the best-trained staff can miss a label or mis-scan an item — and the cost of those mistakes adds up fast.

Fixed industrial scanning solves this problem by removing human variability from the process. Once installed, fixed industrial scanners operate continuously, capturing and verifying every code in their field of view without slowing down your line. This:

- Reduces errors that lead to costly returns, rework, or compliance issues.

- Increases productivity by freeing staff for higher-value tasks.

- Improves traceability so you know exactly where each product has been in your process.

High-Impact Use Cases in Manufacturing, Warehousing & Logistics

In high-volume operations, every second matters — and every error has a cost. Zebra’s fixed industrial scanners are designed to deliver measurable ROI by automating the capture and verification of critical data at speeds and levels of accuracy that manual scanning simply can’t match. In customer deployments, these systems have reduced inspection times by up to 70%, cut shipping errors by over 90%, and eliminated costly rework caused by mislabeled or misrouted goods. By integrating directly with MES, WMS, and ERP systems, fixed scanners feed real-time, error-free data into your workflows, so decisions can be made instantly and confidently.

Here’s how they deliver impact across manufacturing, warehousing, and logistics operations:

Manufacturing

- Assembly Line Inspection – Verify that the correct components are present before the next build stage, preventing downstream defects and warranty claims.

- In-Process Quality Control – Automatically detect and remove defective items before they advance, reducing scrap and increasing yield rates.

- Traceability – Document every part and finished product for compliance and warranty support, with scan data stored directly in your quality or traceability system.

Warehousing

- High-Speed Order Verification – Automatically match picked items against order records, reducing mis-picks and shipping delays.

- Pallet and Container Tracking – Scan multiple barcodes simultaneously without stopping conveyors or forklifts, improving throughput.

- Inventory Location Updates – Instantly update product location when items move zones, keeping WMS data accurate in real time.

Logistics & Packaging

- Shipping/Receiving Validation – Confirm every item is in the correct load before it leaves, eliminating costly returns and customer dissatisfaction.

- Cross-Docking Accuracy – Route shipments to the right dock automatically, even in high-volume facilities.

- Label Verification – Ensure every barcode is correct and legible to meet customer or regulatory standards, reducing chargebacks and compliance issues.

Built for Speed, Accuracy, and Reliability

In manufacturing environments, even small interruptions like a misread barcode or a delayed scan can create larger downstream issues; from slowed production lines to inaccurate shipments. Fixed industrial scanners address these challenges by providing consistent, reliable data capture under conditions where standard scanners often fail. Zebra’s family of fixed scanners are designed to maintain performance in real-world situations, such as variable lighting, high-speed lines, or when labels are damaged or poorly printed. By removing these common points of failure, they help keep operations running smoothly and reduce the risk of costly errors.

- Exceptional Read Performance – High-speed processing and advanced decoding algorithms capture even damaged, poorly printed, or obscured barcodes—far beyond the capabilities of entry-level fixed-mount scanners.

- Industrial Durability – Compact, rugged designs stand up to dust, vibration, shock, and extreme temperatures, making them ideal for manufacturing floors, conveyor lines, and distribution centers where consumer-grade devices simply can’t survive.

- Flexible Connectivity – Multiple industrial protocol options—including Ethernet/IP, PROFINET, Serial, and USB—allow seamless integration with existing PLCs, warehouse management systems, and line controls.

- Scalability – Start with a single station and scale to full-line or plant-wide deployment without replacing hardware, thanks to modular software upgrades and flexible mounting options.

Zebra Fixed Industrial Scanning solutions compete in a category often dominated by other machine vision and industrial scanning brands—but their blend of high-performance scanning, rugged build, and deep Zebra ecosystem integration means they often exceed expectations, including a low total cost of ownership.

The MSM Solutions Integration Advantage

Technology alone won’t transform your workflow — it’s the integration that makes the difference. That’s where MSM Solutions comes in.

With over 30 years of experience delivering barcode automation for manufacturing, warehousing, and logistics, we know how to:

- Configure these devices for your exact process

- Integrate with your MES, WMS, or ERP system

- Support your system with on-site and remote service

- Train your team for maximum uptime and ROI

Our approach is simple: Identify. Track. Count. Manage. It’s not just our tagline — it’s the method that ensures your automation project delivers measurable results.

Why Now Is the Time to Automate

Labor challenges, rising customer demands, and the need for greater visibility make automation no longer optional. With Zebra Fixed-Mount Industrial Scanners, you get a system that works 24/7, delivers consistent results, and scales with your business.

The payoff:

- Lower error rates and rework costs

- Faster order fulfillment

- Stronger compliance and customer confidence

See It in Action

Watch Zebra’s fixed scanning technology in operation, then imagine what it could do for your business.

Let’s Build Your Fixed Scanning Solution

Ready to eliminate barcode errors, increase throughput, and boost your bottom line? MSM Solutions will design, deploy, and support a fixed scanning solution that’s tailored to your operation.