In today’s rapidly evolving world, businesses are increasingly recognizing the importance of sustainability in their operations. This paradigm shift is particularly evident in the logistics and warehouse management sector, where the adoption of eco-friendly practices is gaining traction. In this blog, we will explore the concept of green warehousing, focusing on sustainable practices, energy-efficient automation technologies, and the significance of blockchain in enhancing transparency and traceability in the supply chain.

Environmentally Conscious Warehouse Practices

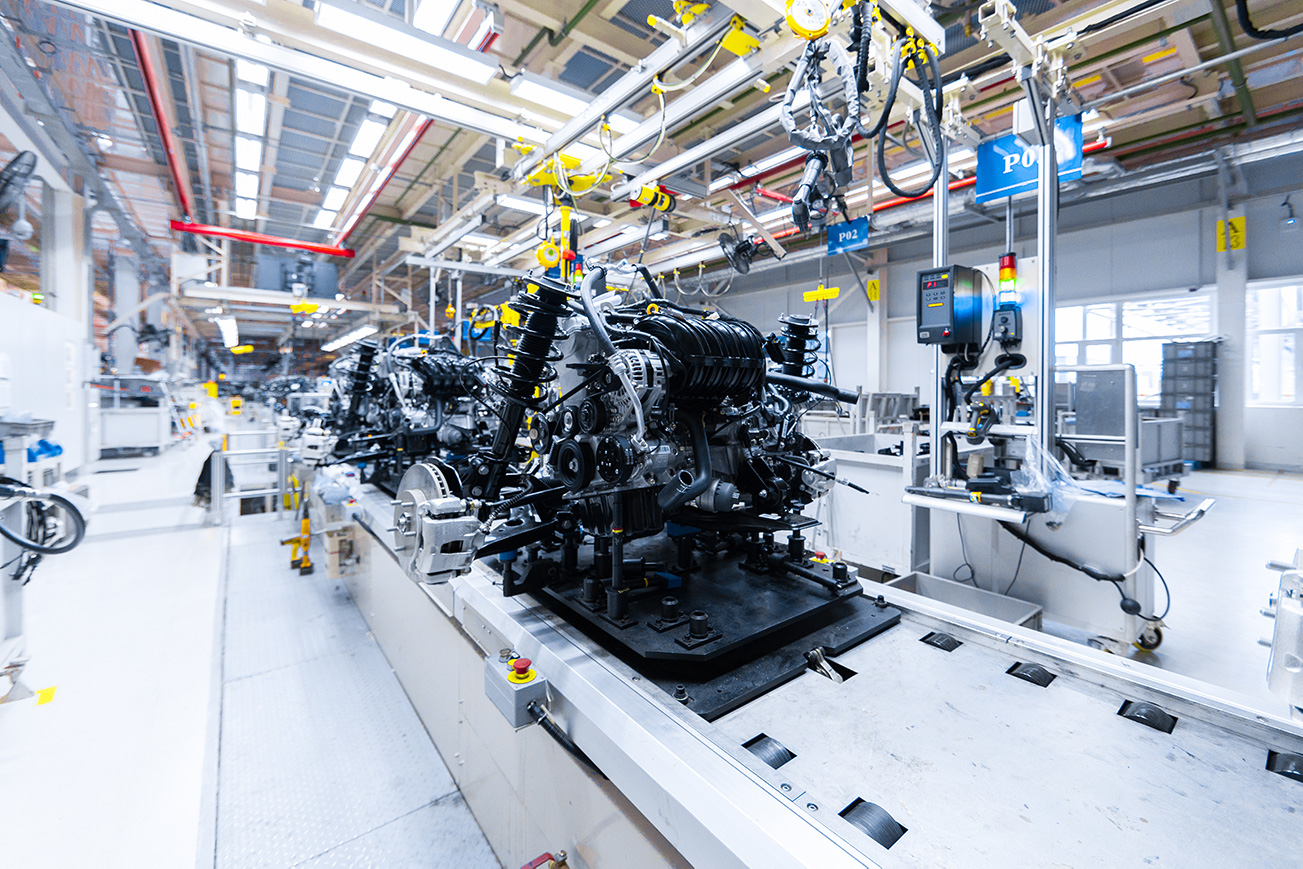

1. Energy-Efficient Automation Technologies

Green warehousing places a strong emphasis on energy efficiency. Automation technologies play a pivotal role in achieving this goal. Advanced Warehouse Management Systems (WMS) leverage smart algorithms to optimize inventory placement and streamline order picking, reducing the energy required for manual operations.

Additionally, automated systems such as robotic pickers and Automated Guided Vehicles (AGVs) from Zebra Technologies are designed to operate efficiently, minimizing energy consumption while maximizing productivity. These technologies not only reduce operational costs but also contribute to a significant decrease in carbon footprint.

2. Sustainable Packaging

Packaging is a crucial aspect of any warehouse operation. Adopting sustainable packaging solutions not only reduces waste but also lowers transportation costs due to lighter and more compact materials. Biodegradable, recyclable, and reusable packaging options are becoming increasingly popular in green warehouses.

In addition, smart packaging solutions integrated with IoT sensors can monitor the condition of goods in real-time. This ensures that perishable items are handled with care, reducing spoilage and further minimizing waste.

3. Renewable Energy Integration

Incorporating renewable energy sources (such as solar panels and wind turbines) into warehouse operations significantly reduces reliance on fossil fuels. By harnessing natural resources, warehouses can generate their own clean energy, and reduce their environmental impact.

There are other small ways to make a big impact too. Consider energy-efficient lighting systems, motion sensors, and insulation techniques that can contribute to overall energy savings. These sustainable practices not only benefit the environment but also lead to substantial cost savings over time.

Eco-Friendly Automation Solutions

1. Green Materials Handling Equipment

The choice of equipment in a warehouse can greatly impact its eco-friendliness. Electric forklifts and pallet jacks, for example, produce zero emissions compared to their diesel counterparts. Battery-powered equipment is not only quieter but also requires less maintenance, making them a greener alternative. In addition, the use of regenerative braking technology in electric vehicles allows them to recharge their batteries during deceleration, further improving energy efficiency.

2. Lighting and HVAC Systems

Implementing intelligent lighting and heating, ventilation, and air conditioning (HVAC) systems can significantly reduce energy consumption. Motion-activated lighting ensures that lights are only on when needed, while smart HVAC systems adjust temperature settings based on occupancy and outdoor conditions. Incorporating natural lighting through skylights and strategically placed windows can further decrease the need for artificial lighting during daylight hours.

Blockchain in Warehousing

Enhancing Transparency

Blockchain technology provides an immutable ledger that records every transaction or movement of goods within the supply chain. This transparency ensures that all stakeholders have access to real-time information about the status and location of products.

By leveraging blockchain, green warehouses can demonstrate their commitment to ethical and sustainable practices, building trust with customers and partners alike.

Ensuring Traceability

Traceability is critical in industries like food and pharmaceuticals, where the origin and handling of products are of utmost importance. With blockchain, each step of a product’s journey can be tracked and verified, from the source to the final destination. This level of traceability not only enhances product safety and quality but also allows for swift and accurate recalls if necessary, minimizing potential harm to consumers and the environment.

Green warehousing represents a paradigm shift towards sustainable and eco-friendly practices in the logistics and warehouse management sector. By adopting energy-efficient automation technologies, implementing sustainable packaging solutions, and integrating blockchain technology for enhanced transparency and traceability, warehouses can reduce their environmental impact while simultaneously improving operational efficiency and customer trust. Embracing these practices is not only a responsible choice for businesses, but also a crucial step towards a more sustainable future for all.

For more information and guidance on creating a greener, more sustainable environment using automated solutions and leading-edge technologies for your business, contact us today.