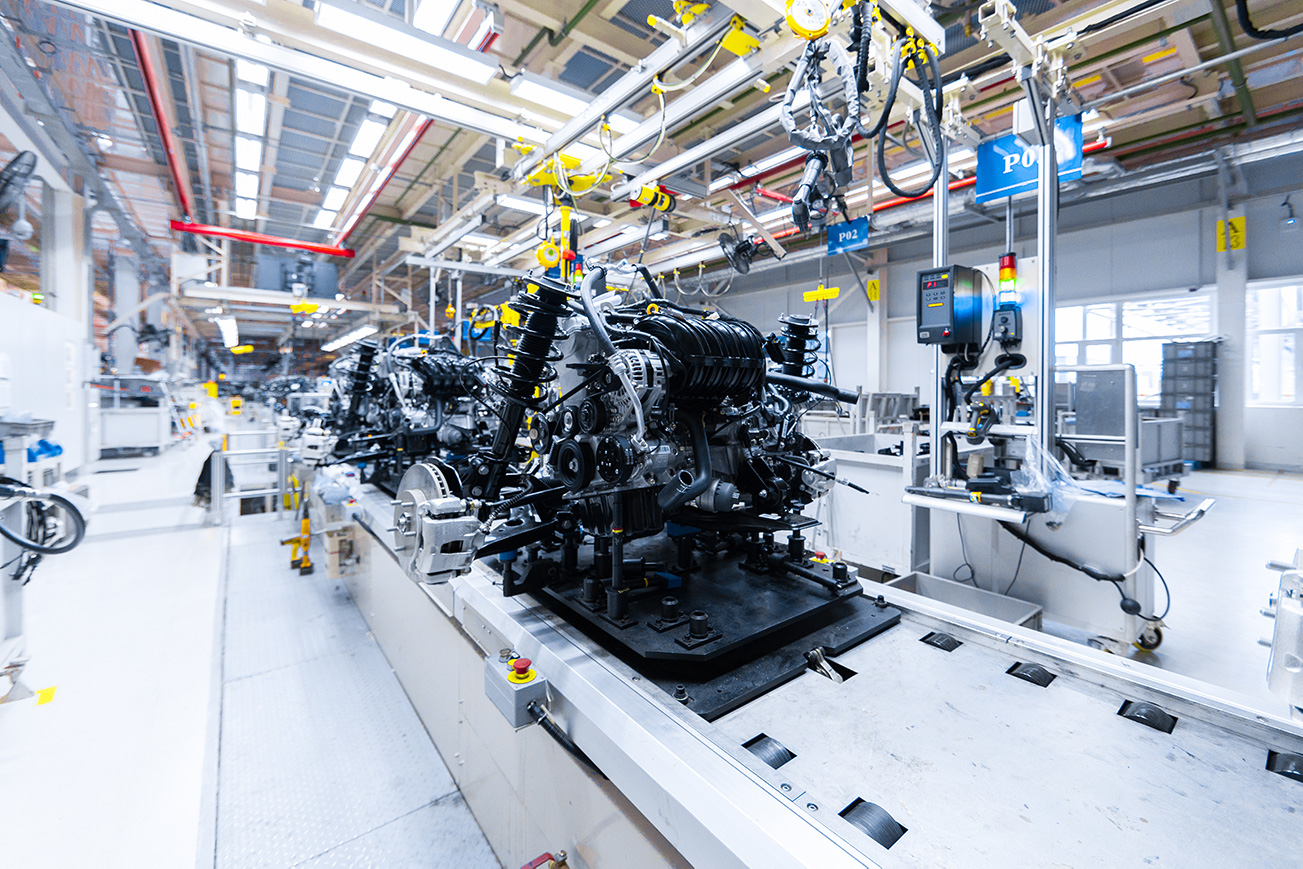

Streamlining workflow management in production, inventory management, and other manufacturing tasks is invaluable in keeping track of all objects. In automotive manufacturing, various components and tools in assembling processes require accurate tagging to expedite production. In the complex production cycles, Radio-frequency identification (RFID) provides automatic identification and tracking of tags for work in progress (WIP). RFID overcomes the challenges inherent in traditional tracking mechanisms. It provides real-time information about objects allowing manufacturers to manage production and supply-chain processes seamlessly.

Adopting cost-effective, scalable, and flexible WIP tracking method promotes efficiency in an automotive manufacturing firm. RFID WIP tracking allows you to know where critical components in the manufacturing process are there at all times. RFID tags are more than identification tools. They carry other information such as size or type of materials enabling you to track your high-value items with ease. You can avoid errors resulting from improper data logging and labeling by utilizing RFID solutions. Since data from RFID work in progress can be synchronized with other data processing systems (ERP systems), you can visualize the production cycles easily using a single platform.

Unsurprisingly, RFID has a robust value proposition making it a critical competitive differentiator. Seamless workflow systems bolster ROI through accurate tracking of WIP assets, unlimited real-time WIP inquiries, and automated WIP reports. Such reports inform decision-making processes at the departmental and executive level. RFID address supply-chain and manufacturing processes that cannot be addressed by alternative technologies like the barcode. It enhances visibility and security by utilizing machine learning and artificial intelligence (AI) in monitoring work in progress.

Software systems used in RFID WIP can be tailored to accommodate a spectrum of alerts, exception handling, or notifications. Such customizations are dependent on the business rules, government regulatory environment, and enterprise best practices. Where assets need to be reused, RFID tags are crucial in preventing low asset utilization, asset loss, and limited visibility. Tracking work in progress can be even more comfortable when you can get alerts or notifications when assets move in and out of the inventory. Regular information about assets in the production process is imperative as it gives managers better visibility of WIP at various manufacturing stages. RFID provides the status of multiple components at each assembly and sub-assembly stage in automotive manufacturing.

Using RFID for Work in Process in manufacturing systems in the auto industry involves:

- Asset tracking and monitoring in real-time

- Monitoring wastage through tagging components in assembling stage, WIP and finished products

- Cutting down on costs by implementing JIT inventory strategies

- Integrating systems to enhance the visibility of the production cycles

- Streamlining supply-chain processes

In our MSM Solutions PortalTrack Automotive Case Study, we examined how manufacturing businesses can integrate RFID systems in their production cycles. We found out that PortalTrack (our RFID solution) resolved issues that are common with traditional tracking systems. RFID adds more functionality to Kanban systems, lean manufacturing, and just-in-time manufacturing (JIT), enabling auto manufacturers to expedite production processes. RFID is a one-stop solution for tracking assets, controlling inventory, and managing supply-chain systems. Leveraging IoT network technology and cloud-based Portal Track software, MSM Solutions created a secure RFID deployment platform for a premium auto manufacturer.