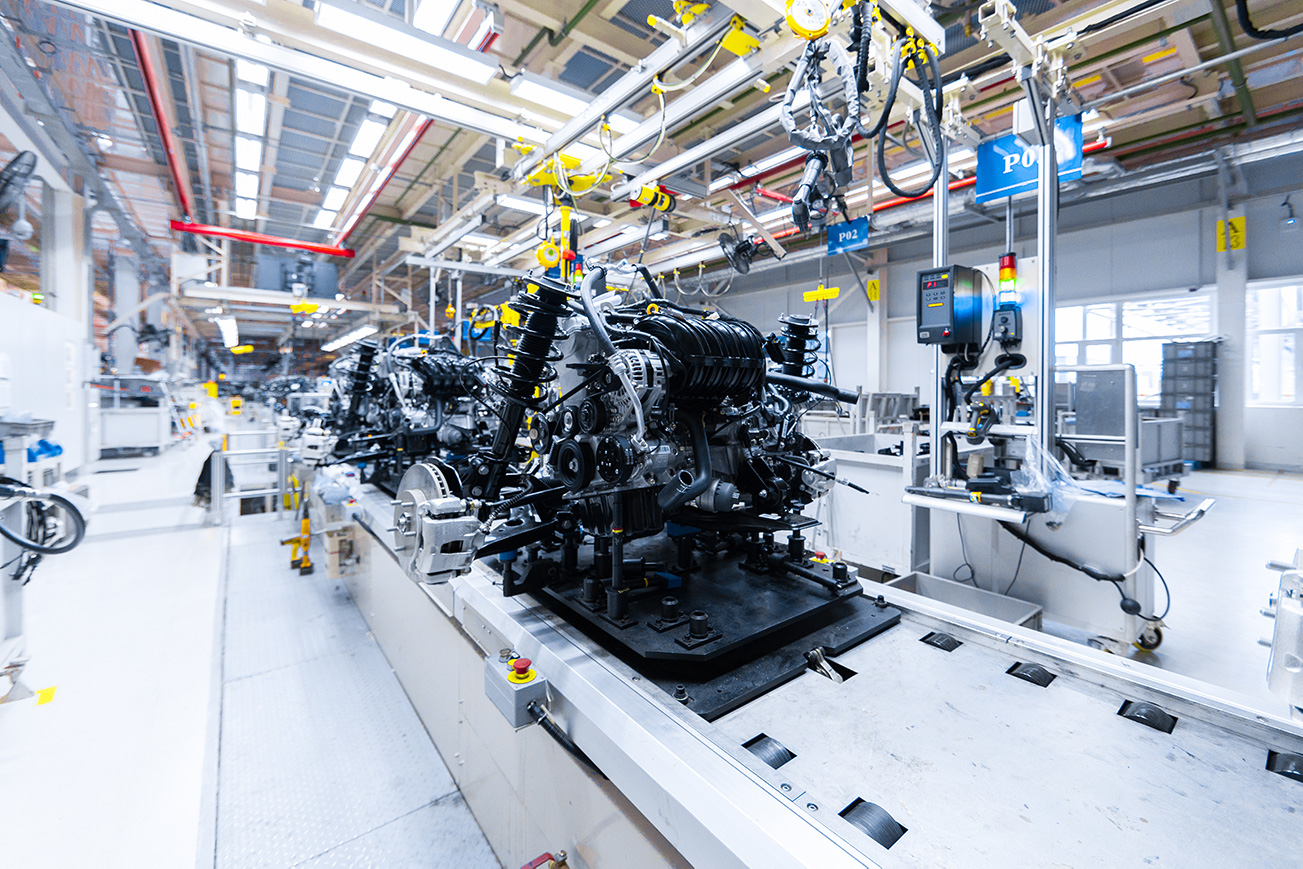

Radio Frequency Identification technology (RFID) presents entirely new opportunities for the manufacturing industry, especially in the production and supply chain processes.

RFID technology in the smart factory has many more complex applications than simply tracking products over long distances. The manufacturing processes can benefit from the information stored in RFID tags in increasingly sophisticated ways, allowing greater flexibility, customization, and efficiency in the manufacturing of products, allowing higher levels of automation and standardization. The results: greater efficiency, greater flexibility, and cost reduction.

The information stored by the RFID tag is a value in itself. The path that the product follows, from production to retail, provides valuable information in these times of Big Data. Since the label is created at the source, manufacturers can obtain deeper knowledge about production control, process optimization, and quality control. The data that can be captured and stored on an RFID tag provides a “digital DNA” with information specific to the production and history of the tagged product; tracking just about any type of information related to the asset and finally, storing all of it in the cloud.

With PortalTrack, “It all starts with a label,” the solution goes well beyond simple encoding by capturing information such as who encoded the item, where the item was encoded, what materials were used to create the item. By capturing more information than any other provider and storing that information in the cloud, PortalTrack users create a blueprint into the production and history of their inventory and assets, allowing manufacturers to fully optimize their operations while maintaining the integrity of the brand.

Additionally, Business Intelligence allows us to process this information; and to follow the product in real time throughout the supply chain and ultimately into the hands of the customer. These volumes of additional information, previously unavailable, provide manufacturers with better tools to execute their business processes and to make better decisions moving forward.

The ability of RFID to capture extensive product information also offers many advantages to the identification process:

- RFID tags identify each individual product.

- RFID technology allows multiple electronic tags to be read simultaneously.

- RFID tags can store substantially more information about a product than the barcode, which can only contain one code and, perhaps, a price or quantity

- While barcodes can be written only once, RFID tags can be written as many times as necessary.

- RFID technology prevents counterfeiting. With a simple photocopy, you can reproduce a barcode. Electronic tags, on the other hand, cannot be copied. A tag on a brand article guarantees its authenticity.

- A barcode breaks down rather easily, while an electronic label is more resistant as it is usually part of the product or placed under a protective surface. An electronic label reads on metal and is protected from humidity and temperature.

PortalTrack can be implemented and customizable to fit the existing process and easily integrated with SAP, Oracle, WMS and other ERP Systems to make the “Identify” step happen. Its cloud-based architecture and real-time information can be delivered on a variety of platforms including Windows, Windows Mobile, iOS and Android. PortalTrack helps drive critical business decisions with web-based dashboards, facility mapping, and email alerts, providing instant access to the manufacturing process.

PortalTrack increases location and inventory accuracy with real-time visibility resulting in better business decision making.