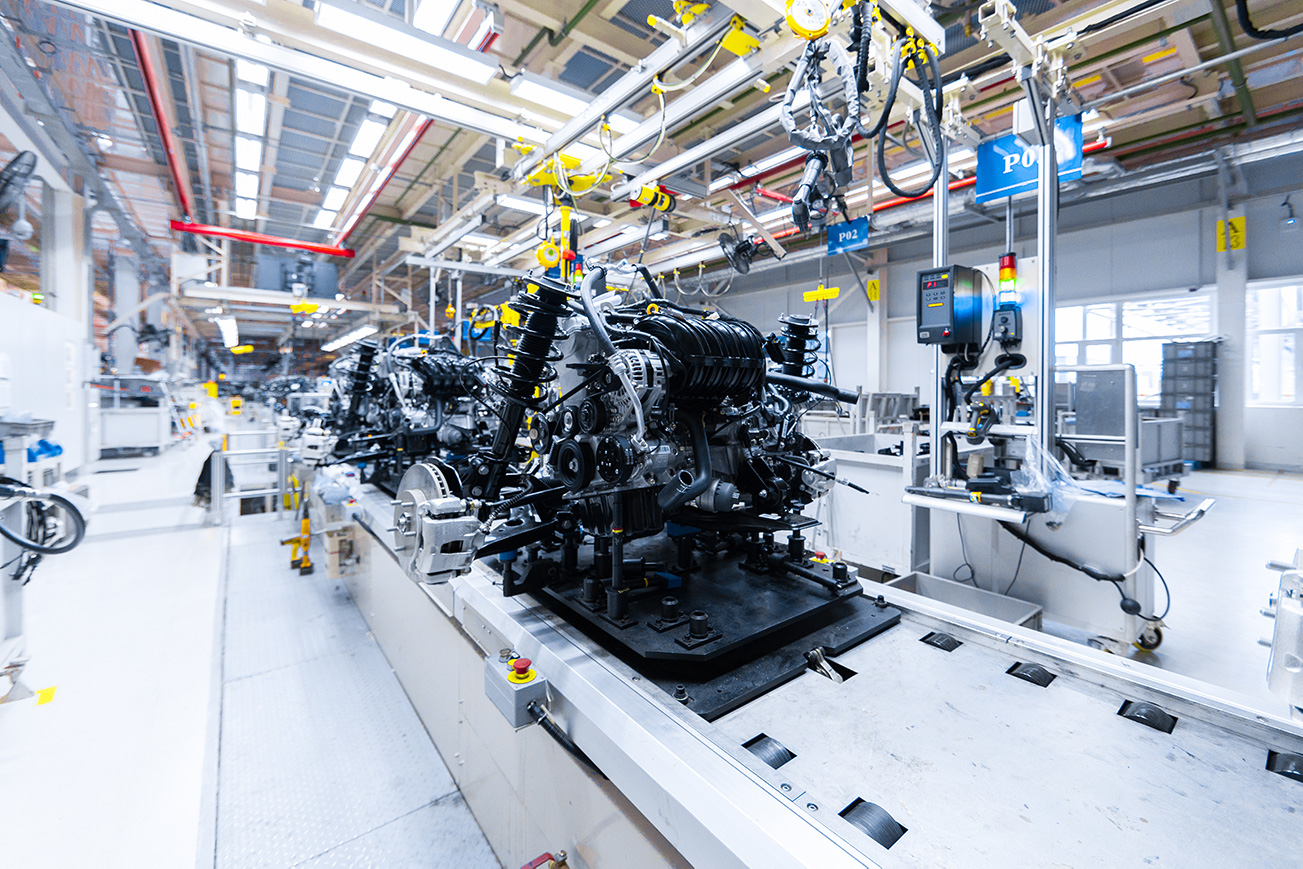

RFID technology optimizes the processes employed by manufacturing companies all around the world. Real-time product information and traceability is now a requirement for these companies in order to maintain sufficient production and storage management operations. Management systems need to be integrated perfectly to leverage information generated and collected by the RFID implementations. This flow of information and traceability streamlines daily operations and optimizes a company’s logistics, production, and management procedures.

The RFID System

An RFID system is built on the following two elements: transponder (or tag) and reader/writer.

The transponder, or tag, is generally a passive, battery-free component composed of an integrated circuit (chip), a capacitor, and an antenna.

The reader/writer is also equipped with an antenna that emits an electromagnetic field. When the transponder enters the reader’s field of action, it absorbs electromagnetic energy from the reader itself, which is converted into electrical energy to charge the capacitor in the tag. When the capacitor receives the charge, it transmits its identification code back to the reader. The transponder is equipped with an internal memory sized from tens of bytes to thousands, depending on the application.

The Management Software

Ideal management software should not only regulate the production processes of the plant and storage area, but also other processes like the receipt and shipment of merchandise, order preparation, pallet validation, warehouse location, etc. To identify the different functions to include in the RFID software management, the application needs to be considered and analyzed in aggregate. Building this software correctly, a company can have automated information on functions previously only controlled manually, such as order generation. Constant change in production volume requirements makes it necessary to have an information system that integrates production with management operations. The amount of information that can be extracted and leveraged from these RFID systems facilitates decision making at many levels, such as the number of items to be produced and even the appropriate production amount of individual model numbers.

Among the most important functions in warehouse efficiency is the physical management of pallet locations on the shelves, in concert with the optimization of the storage areas, since it is vitally important to maximize locations available in the warehouse and to locate pallets. Through RFID management software, a company can locate pallets and individual items on the pallets, without ever having to physically go to a warehouse or storage area. The system stores the locations of each of the pallets, allowing for quick localization and efficient inventory management. Another useful function of the management software is the preparation of orders to be shipped out. Since a pallet is easily located, the operator in charge can know exactly what route to take to physically pick up the merchandise, increasing the productivity of the operator in terms of lines of order prepared by the hour. The right RFID software gives the company greater amounts of information in real-time for the control and management of an array of business processes.

Integration of the RFID System and the RFID Management Software

To be able to benefit from all the advantages of the implementation of the RFID technology in production and logistics, it is necessary to have a solid integration of the information generated by the RFID System with the RFID Management Software.

This integration allows for the real-time flow of information from the RFID readers to the management software. The software can analyze the data and automate once-manual functions, like the process of receiving the merchandise. In this process, for instance, merchandise enters a warehouse and passes through an RFID antenna which identifies each pallet, each box, and each item. This information is transmitted to the management software and either validates and confirms the shipment or reports and an error in the order. This integration, with specific software developed, is achieved through a middleware or interconnection platform between the two. The middleware is responsible for handling the information captured by the radio frequency antennas, from each and every tag. The middleware manages the antenna readings and then processes it through the production and warehouse management software. The transfer of information is carried out directly on the system’s database, resulting in fast and effective processing with a significant error reduction, all in real-time.

Conclusion

The implementation of RFID technology and its integration with the right management software provides a company with great advantages in its production and logistics processes. The primary benefits of implementing RFID is the speed and agility gained throughout these work processes, the reduction of errors caused by the operators, and access to a great amount of information generated in real-time. Offering a complete management of the warehouse, as well as real-time inventory control, the time spent receiving and shipping merchandise is reduced, loss items are reduced as well as warehouse operators’ time, and production levels are increased along with greater quality controls in the validation of pallets and products.

Through the unique and unequivocal identification of each pallet and box, providing total traceability throughout the entire production process and facilitating the identification and location of items at any given time, a secondary but vital benefit is the improved processes outside of the primary production and warehousing processes, including enhanced decision-making ability based on captured information, better management of the transportation of goods, and improvements in forecasting, all thanks to an integrated RFID System.