How to keep things connected from manufacturing to distribution to delivery with RFID Supply Chain

If you spent any time shopping for groceries in the past six months, you probably have firsthand knowledge of the disruptions the COVID-19 pandemic has caused within our supply chains. Remember the hunt for toilet paper? It was like finding the golden ticket to visit Willy Wonka’s Chocolate Factory. And we’re still struggling to find disinfectant wipes.

With many companies reliant on manual barcode scanning or physical counts to keep track of dwindling inventory, the loss of labor due to COVID-19 put even more strain on already sluggish logistic processes.

Companies had to contend with limited or complete shutdowns, which resulted in a reduced workforce. Manufacturing, distribution, retail stores – they all had to stop working and the entire supply chain slowed to a crawl. To compensate, companies learned how to do more with less. Some companies were already at their breaking point, so the disruption increased this burden exponentially.

RFID Supply Chain Solutions

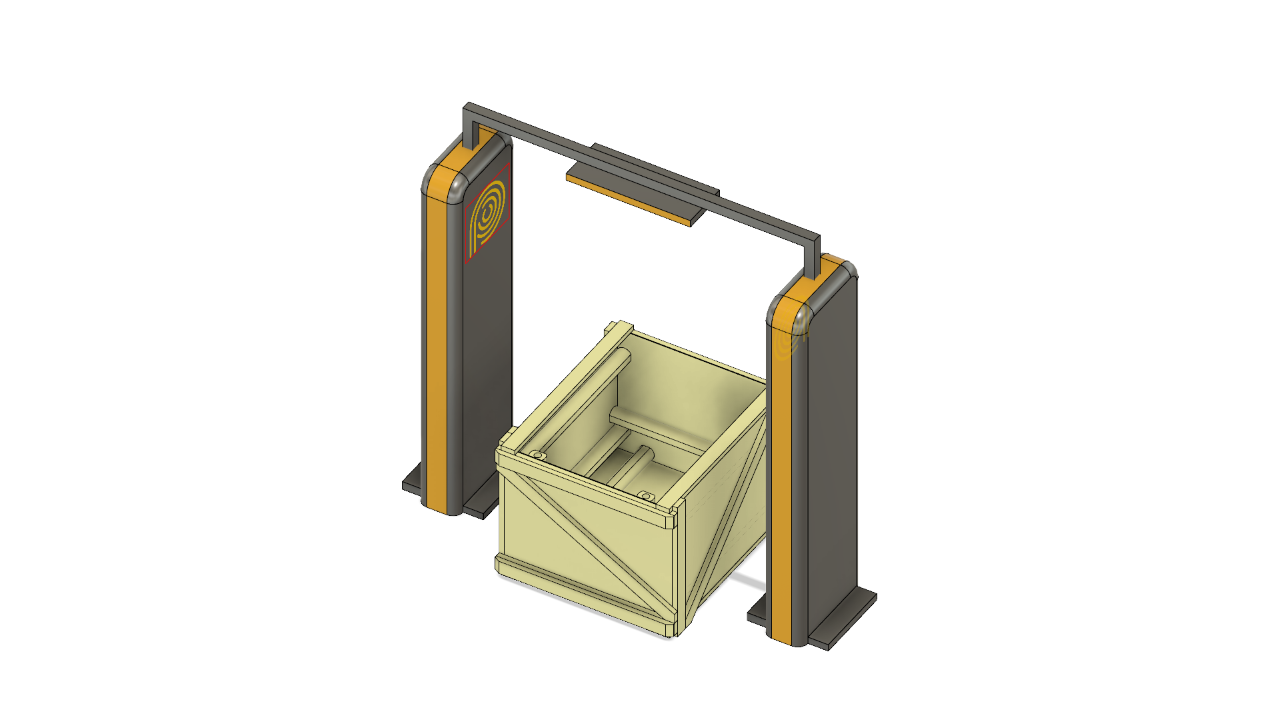

In a simpler time, it was reasonable to hire someone to document or manually scan every pallet or piece of inventory coming off a truck. However, in today’s environment, it’s much easier and more efficient to tag each item with an RFID tag and put it on a conveyor line flanked by RFID readers and RFID Portals that scans it automatically.

MSM Solutions takes it a step further, installing freestanding RFID portals at every dock door in your facility. Inside each portal is an RFID reader with two RFID antennas that begin scanning whenever anything passes in front of the photo eye. The reader scans every pallet that passes through the portal and counts the inventory it’s carrying.

If you have an established inventory list, you can make sure you received everything that was shipped. If not, the RFID solution creates one for you.

In addition, each pallet can be tracked within the warehouse so you know its general location. This is particularly important when you’re working in a 700,000-square-foot facility where you could easily lose a pallet. With RFID zoning, you can create zones with a 50-foot radius so when it’s time to pull assets and ship them to their final destinations, you know the location of each pallet and can quickly find what you need.

Identify, Track, Count and Manage

MSM Solutions believes that efficient RFID supply chain management is based on four actions: Identify, Track, Count and Manage. Using conveyor lines, portals and zoning systems, RFID automation makes your business more efficient by tracking what you have and identifying its location.

MSM Solutions can scan every asset as you load it onto a pallet for shipping. If a shipment leaves with 500 assets, the receiving party can confirm the inventory by verifying the DPC numbers on the pallet. Not only can you ensure the count is right; you can also verify that the product delivered is correct.

Whether your business is a hospital, a department store or an automotive manufacturer, your inventory is important to the success of your business. We focus on helping you track, count and verify every asset you receive or ship out.

Ready to learn more about how MSM Solutions can reduce supply chain disruptions now and for the future? Drop us a line and find the right RFID solution for your business.