The concept of logistics tracking refers to identifying the origin of a product and any of the different stages that the product goes through, from the beginning of the production process, through its subsequent distribution, and to arriving at the final consumer.

What is a Tracking System in Logistics?

A proficient tracking system includes a set of procedures that provides the ability to follow a product through the supply chain; to trace its route and anticipate the path it will follows.

A tracking system can establish a direct relationship between the physical flow of goods and the flow of information that is associated with it.

The Advantages of a Logistics Tracking System

- For companies: A Logistics Tracking System helps companies identify critical points throughout their supply chain in order to solve problems quickly and increase productivity. Through logistics tracking, they can reduce problems related to mishandling or contamination of goods, thus increasing the quality of output.

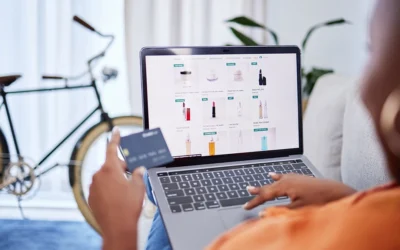

- For consumers: Consumers benefit through improved confidence when buying products and services that are monitored throughout their supply chain, especially in a globalized economy with complex flows of national and international merchandise. With the rise of e-commerce, the traceability of merchandise has come to the forefront, since it attenuates “traffic uncertainty” that many online buyers suffer and is conducive to the new paradigms of omni-channel logistics and e-logistics.

- For authorities: Particularly in key sectors related to public health, like pharmaceuticals and food production, tracking systems are mandatory and have been highly regulated for years.

Types of Logistics Tracking

- Tracking/Tracing Backwards: Tracking backwards can be used to identify the origin of any specific batch or unit of cargo. It allows manufacturers and regulators to explore the stages that a product progresses through from conception to the final delivery, which can include the identification of raw materials used and individual production operations carried out for the unit.

One example of this traceability application is to address a health alert for food contamination when backward tracking can determine where an adulterated batch has been produced or contaminated within the supply chain so producers can remove it from the marketplace.

- Tracking/Tracing Forward: Forward tracking refers to the capability of monitoring the route that a cargo unit or batch will travel. In this way, we can predict the optimal way to travel, for example, to make an estimate time or date of delivery. This tracing is most used to report the steps that the product will follow to its final destination for online purchases.

A common pattern of the stages of monitoring or tracking forward is as follows:

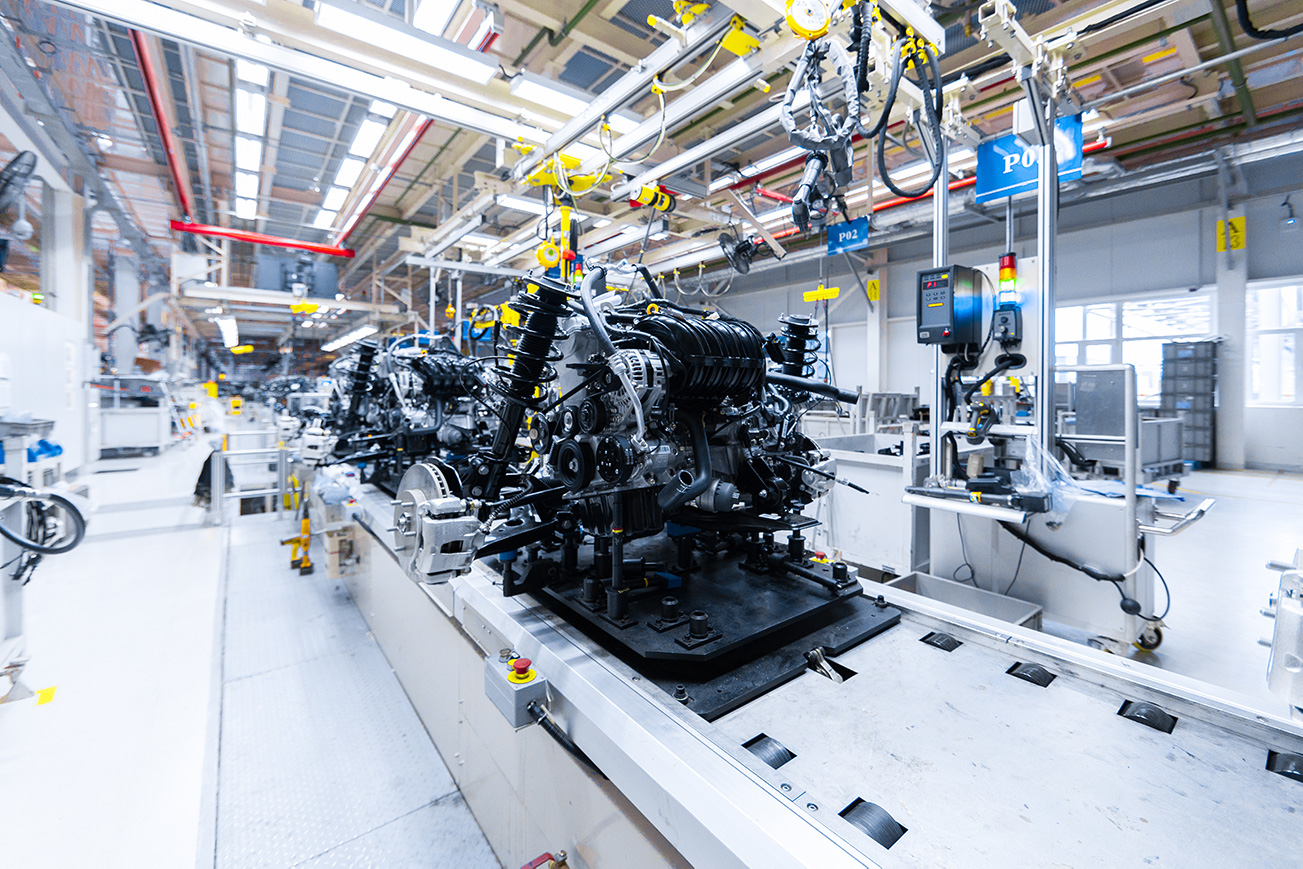

- Internal Tracking: Internal tracking or traceability involves the trajectory of products through the company’s production chain until they are shipped. The great challenge for this type of traceability is to meet the demand of providing great detail regarding the delimitation, identification, and recording of all the movements and manipulations that the product follows.

This can be easily accomplished in the case of a storage application, thanks to SKU coding and the use of a warehouse management system for inventory management. However, a food production company can be required to know and report each mixture of raw materials, and even semi-finished products must be catalogued and regulated.

- External Traceability: External traceability is a system of identification and registration that is projected beyond the limits of the company itself. It covers all the links that make up the supply chain until it reaches the customer or consumer, including, perhaps, transit through different countries carried out by external agents. For these reasons, the coding system must be able to be shared by all agents involved in the flow of goods. Thus products need to have more universal traceability, not only internal identifications (such as SKUs).

Elements of a Product Tracking System

1. Formulas for Unique Identification and Codification of Goods

One of the pillars on which logistics traceability is based is the unique identification of the cargo units or batches. The integration of this information in the supply chain is only possible thanks to the deployment of a standardized language shared with all those involved that facilitates the registration of data in an automated way.

The two most widespread identification systems are

- Barcodes: Barcodes are currently the most widely used product identification method worldwide. This system uses a common language to create unique codes and thus identify products thanks to a series of numbers with their equivalent in the form of bars. The GS1 organization established coding standards for different types of information linked to each product based on a GTIN, or Global Trade Item Number. This number may be accompanied by others that add additional information such as a batch identification, a SIN or Shipment Identification Number, or a SSCC, or Serial Shipment Container Code, among others.

- RFID (Radio Frequency Identification): In the case of Radio Frequency Identification, an RFID tag itself is capable of transmitting data thanks to radio frequency waves. These tags store the accompanying product information, and most are activated when they are detected by a nearby reader. RFID requires a simpler formula than barcodes but it is more expensive to implement. The main and very useful advantage of RFID is that it does not require a direct line of sight for the extraction of identification information from a tagged product, dramatically improving the speed and precision of records.

2. Data Capture and Recording Systems

Once the products have a standard coding system, a system is needed to download this information into specialized software. Data capture devices act as a bridge between the physical and digital worlds.

The devices “read” and register the coding information and transmit it to a software database. Readers can be barcode readers, temperature and humidity sensors, and/or RFID antennas or arcs. In warehouse applications, these systems can be integrated at the point of entry or on automatic systems such as conveyors. Voice picking or voice-directed warehousing (VDW) devices are also included in this section.

3. Data Processing Software

The union of the information flow with the physical movements of the merchandise is only possible thanks to an integrated computer system that gathers all data, processes it, and shares it among all those involved. This data processing software collects, stores, and structures the information regarding the production and transit of the product in a customizable, coherent way. It generates effective links between the devices, products, and agents involved throughout the entire supply chain.

The main types of software used in tracking systems are the following

- Business Management Systems or ERP: ERP works as an integrating software where different sources of information can be collected from core areas of the company including sales, accounting, production, stock management, human resources, etc. It is usually the base system with which every company operates.

- Warehouse Management Systems or WMS: WMS is a powerful software that optimizes all the material flows that take place in the warehouse. Every step that a product takes is registered and communicated from this to the ERP and the rest of the systems with which the company works.

- Transport Fleet Management Systems or TMS (Transport Management System): TMS organizes and plans delivery routes. Especially in e-commerce shipments, it is usually the software responsible for notifying the customer of the follow-up. For greater process agility, it can be integrated with the GHS (Globally Harmonized System of Classification and Labelling of Chemicals) to unify labeling and the exchange of information between systems.

- Supply Chain Event Management System (SCEM): SCEM controls all the information related to logistics flows, and can notify in eventual incidents. It ensures that each person involved in a process can fulfill their role, and avoids breakdown in the information chain that feeds the traceability system to prevent tracking failures.

In conclusion, logistics tracking systems are designed to improve security of goods, control risks, and guarantee the quality of processes and products. If you want to know how our PortalTrack software can contribute to the optimum operation of your tracking system, do not hesitate to contact us.