Why Inventory Visibility Matters

Inventory visibility is what truly drives effective inventory management, providing businesses with real-time insights into stock levels, locations, and movement. Without clear visibility, companies risk stockouts, overstocking, lost sales, and inefficiencies that drive up costs. In today’s climate, businesses must leverage modern inventory visibility solutions to optimize supply chain operations, improve order fulfillment, and meet customer expectations.

With multiple sales channels, growing customer demands, and complex supply chain networks, companies can no longer rely on manual processes to manage inventory effectively. Instead, businesses need automated solutions that provide real-time tracking, demand forecasting, and integration with enterprise resource planning (ERP) systems.

The Role of Barcode Automation in Inventory Visibility

One of the most efficient ways to improve inventory visibility is through barcode automation. Barcode technology enhances accuracy, efficiency, and data-driven decision-making, offering companies the ability to manage inventory with greater precision.

Barcode automation systems track products as they move through the supply chain, from the moment they arrive at a warehouse until they are shipped to customers. Employees use handheld, hands-free, or vehicle-mounted mobile computers like those from Zebra Technologies to scan barcoded materials at various points along the supply chain, updating inventory data in real-time. This eliminates manual entry errors and provides an accurate picture of stock levels, location, and movement.

Key Benefits of Barcode Automation for Inventory Visibility

- Real-Time Inventory Tracking

Real-time tracking is one of the biggest advantages of barcode automation. As products are scanned in and out of the warehouse, inventory data updates automatically. This helps businesses:

- Identify low stock levels and replenish inventory before running out.

- Avoid overspending on unnecessary stock replenishment.

- Provide customers with accurate information on product availability.

- Improve order fulfillment and reduce delays.

For example, if a company selling seasonal products sees an unexpected surge in demand, real-time insights from barcode automation can alert them to reorder before stock runs out.

- Reduced Human Error

Manual inventory tracking is prone to errors, leading to misplaced products, miscounts, and inaccurate data. Barcode scanning eliminates these risks by automating data entry, ensuring:

- Higher inventory accuracy.

- Faster inventory reconciliation.

- Fewer stock discrepancies and fewer costly mistakes.

Accurate data allows businesses to make informed purchasing decisions, improving stock allocation and optimizing supply chain efficiency.

- Enhanced Warehouse Efficiency

Warehouse employees spend significant time locating and managing inventory. Barcode automation reduces the time and labor required for these tasks by streamlining workflows. With barcode scanners, employees can quickly:

- Locate specific products in large warehouses.

- Perform inventory audits in minutes instead of hours.

- Optimize warehouse organization by ensuring proper stock placement.

This increased efficiency allows businesses to allocate resources more effectively and focus on other strategic priorities such as customer service and product innovation.

- Improved Demand Forecasting and Cost Management

Inventory visibility plays a crucial role in demand forecasting. With accurate, real-time data, businesses can:

- Predict customer demand more accurately.

- Reduce carrying costs associated with excess inventory.

- Ensure optimal inventory levels to meet market demand.

By analyzing sales trends and stock movement, businesses can adjust their inventory strategies, reducing financial losses and increasing profitability.

Overcoming Common Inventory Visibility Challenges

Even with advanced inventory tracking solutions, businesses face challenges in achieving full inventory visibility. Some of the most common obstacles include:

- Managing Inventory Across Multiple Sales Channels

With omnichannel retail becoming the norm, businesses must synchronize inventory across physical stores, e-commerce platforms, and third-party logistics (3PL) providers. A barcode-enabled inventory management system helps maintain consistency across all channels, ensuring that customers receive accurate stock information regardless of where they shop.

- Lack of Integration with ERP and Supply Chain Management Systems

For real-time inventory visibility to be effective, it must integrate seamlessly with ERP and warehouse management systems (WMS). Companies should invest in scalable inventory visibility solutions that work with their existing technology stack to avoid data silos and inefficiencies.

- Dependence on Manual Processes

Many businesses still rely on outdated manual processes that hinder inventory accuracy. Implementing automated solutions such as barcode scanning, RFID tracking, and AI-powered analytics eliminates inefficiencies and allows companies to leverage real-time insights for better decision-making.

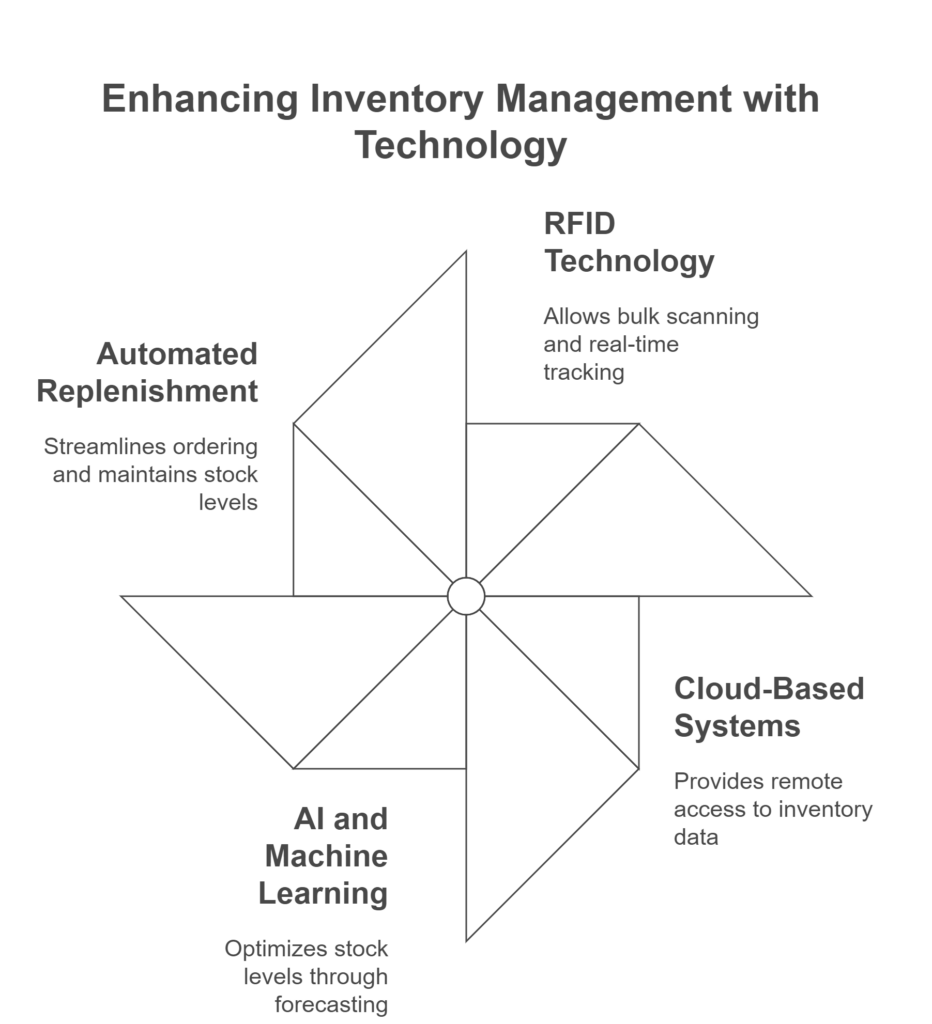

Leveraging Technology for Enhanced Inventory Visibility

Barcode automation is just one part of a broader inventory visibility strategy. Businesses can further improve their inventory management by adopting:

- Radio Frequency Identification (RFID)

RFID technology allows for bulk scanning of inventory, reducing the need for manual checks. Unlike barcodes, RFID tags can be read without direct line-of-sight, making it easier to track inventory in real-time across warehouses and distribution centers.

- Cloud-Based Inventory Management Systems

Cloud-based systems provide remote access to inventory data, enabling businesses to monitor stock levels, generate reports, and analyze trends from any location. This is especially beneficial for companies with multiple warehouses or retail locations.

- AI and Machine Learning for Demand Forecasting

AI-powered analytics help businesses anticipate inventory needs based on historical sales data, seasonal trends, and market conditions. By leveraging AI-driven forecasting, businesses can optimize stock levels, minimize waste, and improve customer satisfaction.

- Automated Replenishment Systems

Automated replenishment solutions streamline stock ordering by triggering restocking alerts when inventory reaches predefined thresholds. This ensures businesses always have the right amount of stock without excessive overordering.

The Future of Inventory Visibility

As supply chains become more complex, inventory visibility will continue to be a top priority for businesses looking to improve operational efficiency. Emerging technologies such as blockchain, IoT sensors, and predictive analytics will further enhance inventory tracking capabilities, reducing losses and optimizing supply chain performance.

Companies that invest in robust inventory visibility solutions today will be better positioned to adapt to future market challenges, improve order fulfillment, and meet evolving customer demands.

Take the Next Step Toward Smarter Inventory Management

If your business is struggling with stock discrepancies, fulfillment delays, or inefficient manual processes, it’s time to invest in a modern inventory visibility solution. Barcode automation and real-time tracking can help you optimize your supply chain, reduce costs, and improve customer satisfaction.

Contact us today to learn more about how barcode automation and inventory visibility solutions can transform your business. Our experts can help you implement the right technology to gain real-time insights and streamline your inventory management process.

Unlock the power of inventory visibility and take your business to the next level!

Achieving Greater Inventory Visibility

Inventory management is an essential aspect of running any business. Proper inventory management ensures that businesses have the right products in the right quantities to meet the demands of their customers. One critical component of inventory management is inventory visibility, which refers to the ability to see what products are in stock, where they are located, and how much of each product is available. With greater inventory visibility, businesses can make informed decisions in an effort to control costs and increase operational efficiency.

Barcode automation systems offer a powerful solution for improving inventory visibility. These systems use barcode technology to track products as they move through the supply chain, from the moment they arrive at the warehouse until they are sold to customers. Barcoded materials can be scanned at various points along the supply chain to update the inventory database. Using a barcode scanning enabled handheld, hands-free or vehicle-mounted mobile computer, employees can safely and accurately update inventory status or easily locate materials using data gathered in real-time.

Key Benefits of Barcode Automation

One of the key benefits of using a barcode automation system is that it provides real-time inventory visibility. As products are scanned in and out of the warehouse, the inventory database is updated automatically, providing an accurate and up-to-date view of what products are available at any given time. For example, if a particular product is selling faster than anticipated, the data gathered by the system can provide valuable information that will alert the organization so they can avoid back-order situations and unexpected stockouts.

Another benefit of using a barcode automation system is that it reduces the risk of human error. Manual inventory management is time-consuming and prone to errors. With barcode technology, products are scanned automatically, reducing the risk of miscounting or misplacing products. This improved accuracy is what enables better decision making. The more reliable the data is that is coming in, the more effective the results will be for purchasing and allocating stock.

Barcode automation systems can also improve worker efficiency in the warehouse. By automating the process of scanning products in and out of the warehouse, businesses can reduce the time and labor required to manage inventory manually. This increased efficiency allows businesses to focus on other aspects of their operations, such as customer service and product development.

Meeting Demands in Today’s Environment

With real-time visibility and accurate data, management can identify trends in their inventory levels and make adjustments as needed. For example, if a particular product is not selling as well as anticipated, the business can adjust their purchasing to avoid overstocking that product.

Greater inventory visibility is essential for businesses looking to improve their operations and meet the demands of their customers. Barcode automation systems offer a powerful solution for improving inventory visibility, providing real-time visibility, reducing the risk of human error, improving efficiency, and helping businesses track their inventory more effectively. By investing in a barcode automation system, businesses can improve their inventory management and position themselves for success in an increasingly competitive market.

If you are looking to improve your inventory position and move from paper-based, manually processes to something more automated, contact us to get an expert opinion and recommendations toward a more automated inventory management solution.