It’s no secret that the current supply chain is broken, and we already know what’s to blame. The COVID-19 pandemic created disruptions in the global supply chain beginning in early 2021 that continue to linger despite multiple vaccines and fewer daily cases.

To understand where we are and what we can do to cope with this enormous problem, we need to understand how we got here and the challenges we continue to face.

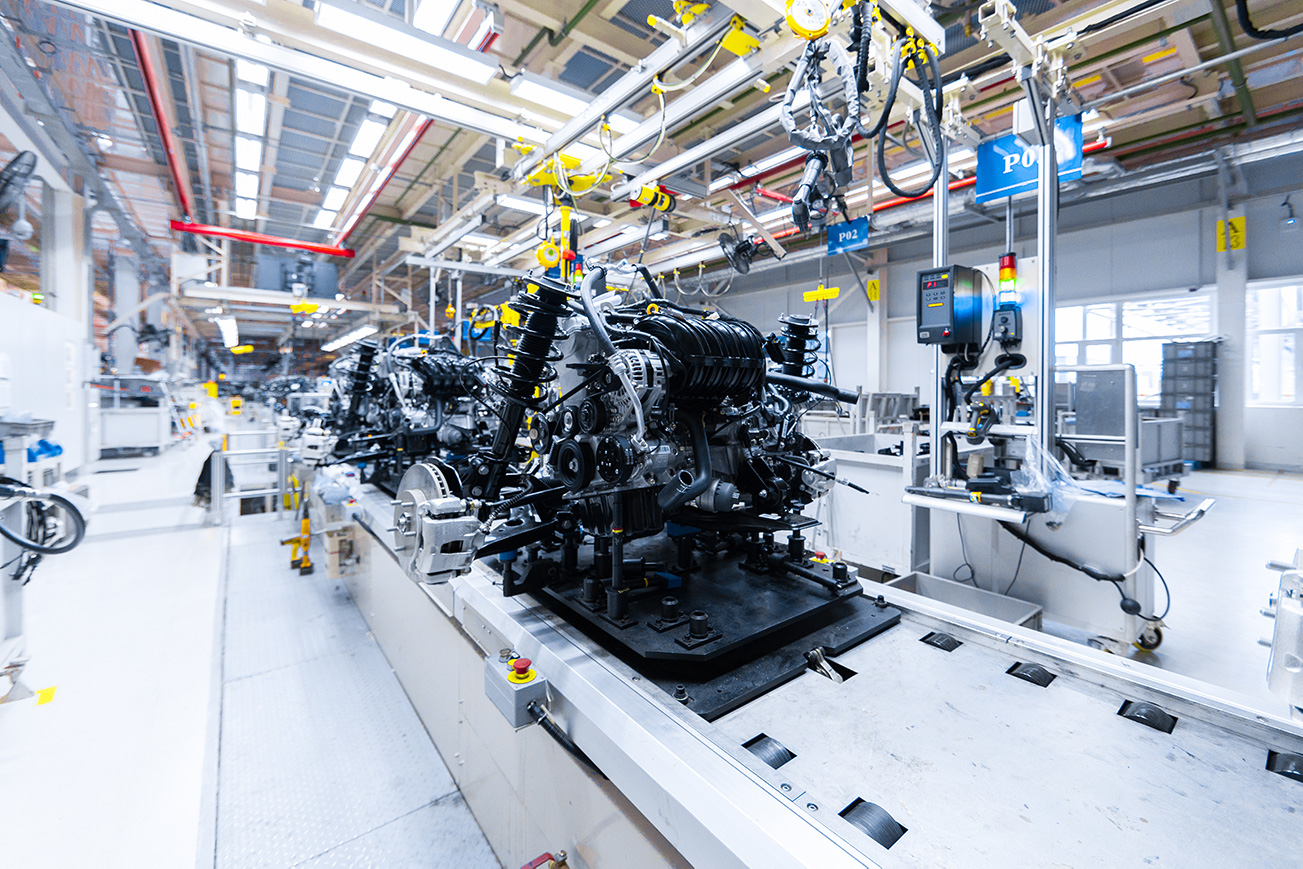

Manufacturing Delays

In the world’s biggest manufacturing hubs like China, South Korea, and Germany, factories shut down due to lockdowns and an anticipated reduction in orders.

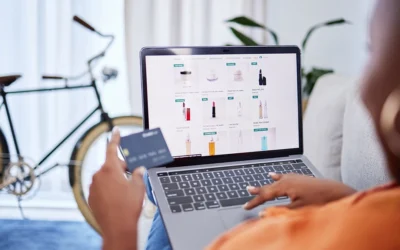

However, a funny thing happened in the United States – something manufacturers didn’t anticipate. Americans used the money saved on cancelled vacations and dinner reservations to buy new furniture, electronics and supplies for our homes that now double as offices, classrooms, and restaurants.

The unprecedented demand for consumer goods exploded. This, combined with the overwhelming need for PPE supplies to protect humanity from COVID, swamped the system and created a backlog of orders that manufacturers struggled to keep up with.

The Cost of Shipping

Once manufacturers got back on track and began meeting their orders, this led to another major problem – the shipping industry was strained as they didn’t have the shipping containers they needed to move goods around effectively.

As the demand for shipping intensified, the average price of moving a container overseas from Shanghai to Los Angeles rocketed from $2,000 to $25,000. Trucking and intermodal transport spiked as well, with prices leaping by double digits due to labor shortages and rising gas prices.

Port Congestion

As cargo ships finally reached their destinations, they were forced to anchor out at sea for days waiting for an open berth to unload their containers. In October 2021, more than 50 cargo ships clustered together outside Long Beach, and Los Angeles overflowing with goods from China.

Labor Shortages

However, getting bottlenecked ships into port didn’t solve the problem. A shortage of dockworkers, truck drivers and other logistics personnel – kept from their jobs by illness or quarantine – forced ports and warehouses to fill up with goods with no way to deliver them to their final destinations.

When Will It End?

The short answer – not any time soon.

Granted, with new vaccines and other medicine hitting the shelves, along with fewer daily cases, we are experiencing some form of recovery. However, it’s going to take time because of ongoing issues:

- Manufacturers are still struggling to get what they need to create their goods

- High demand and bottlenecks slowed international trade

- The pandemic has created a severe labor shortage

- Severe weather events limited access to crucial material sources

Additionally, while some manufacturers have laid out plans to build new factories to create more goods to meet demand, it will be some time before it makes an impact on the current supply chain.

In order to not only survive, but thrive in 2022’s supply chain reality, businesses need to find real solutions that help them work smarter, not harder, to meet the demands of their customers.

Working Smarter with MSM Solutions

At MSM Solutions, we believe most businesses can find success in even the most difficult situations by finding an RFID solution that helps them accomplish four things:

- Improve efficiency

- Increase speed

- Enable better accuracy

- Do more with less

By combining dependable RFID technology like tags, labels, fixed readers, handheld readers, and RFID antennas with MSM Solution’s PortalTrack, you’re able to stay connected with your assets and inventory, giving you better control and insight into your business.

PortalTrack allows you to identify, track, count, and manage your inventory and assets in real-time without human interaction. By creating digital DNA for your assets, you can manage your supply chain and logistics operations more efficiently, more accurately, and faster while employing a smaller labor force.

For critical industries like retail, healthcare, manufacturing, warehousing, and logistics, MSM Solutions uses RFID technology to help companies work smarter, not harder. To learn more about how MSM Solutions can help you gain better control and insight into your supply chain, click here to connect.