In recent years, a series of innovations have emerged to bring the manufacturing industry into a new evolutionary stage. The increased use of automation, combined with connected smart devices and real-time data systems, is enabling new levels of flexibility, speed, and operational visibility. Among these technologies, RFID in manufacturing has become a key driver that allows real-time tracking, digital twin analysis, process automation, and more informed decision-making.

Today, the advanced level of intelligence realized in manufacturing processes is possible thanks to new technologies including Digital Twin, Business Intelligence (BI), Artificial Intelligence (AI), Internet of Services (IoS), the Internet of Things (IoT), and cloud-based industrial systems. These technologies allow the forward-thinking manufacturers to improve their production processes by analyzing large volumes of data, providing a deep and clear understanding of how processes work, with enough detail to identify problems and take corrective action translating into more effective and productive operations.

The introduction of these technologies is often referred to as intelligent manufacturing solutions or Industry 4.0, which represents a shift toward smarter, more connected production environments. Manufacturers can now access real-time data across every stage of production and distribution, regardless of scale or location. This level of insight helps improve efficiency, reduce delays, and support more agile decision-making.

RFID is crucial to making these systems function effectively in real-world manufacturing environments. It captures accurate data at every step of the supply chain, providing teams with better visibility into inventory, reducing manual steps, and facilitating easier product tracing from start to finish. It also extends value beyond the factory floor by supporting post-sale engagement, warranty tracking, and overall customer satisfaction.

What the Future of RFID in Manufacturing Looks Like

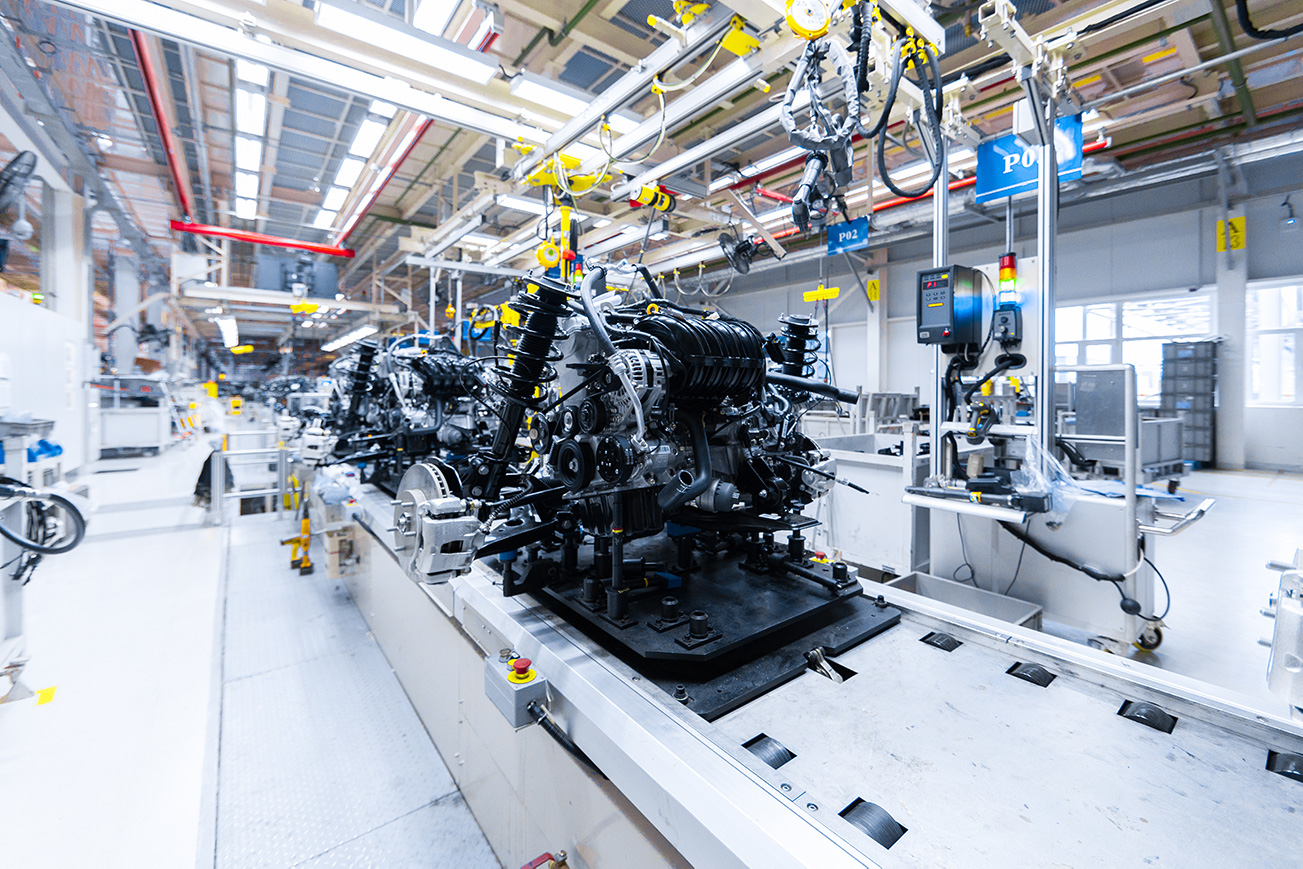

RFID technology in the smart factory has much more complex applications than mere product tracking over long distances. Manufacturing processes can now capture, and leverage information stored in RFID tags in increasingly sophisticated ways, allowing greater flexibility and efficiency in the manufacturing of customized products and enabling a higher level of automation and standardization than ever before. See how it works in our Automotive Case Study.

There are a variety of RFID labels that can be adapted to different products and surfaces and that store several kilobytes of data. Reading and processing the data requires only milliseconds.

Keep in mind that in the face of similar technologies such as barcodes, RFID tags have several advantages in the smart factory. For example, RFID technology allows wireless product tracking. There is no need to be connected to the product, touch it, or put a reader a few centimeters from the product to obtain information. RFID labels can be read from several meters away without line of sight.

RFID tags do more than store product information. They enable the tracking of each item as it progresses through the entire production process. With that kind of visibility, manufacturers can better understand how their operations are performing—from the factory floor to the final delivery. When used with Business Intelligence systems or data mining applications, RFID data becomes a powerful part of any Big Data strategy. It supports just-in-time and just-in-sequence production and helps improve quality, process control, and overall efficiency.

Business Intelligence technologies, as we said before, then allows us to process this information, making it possible to follow the product throughout the supply chain and learn about its interaction with the customer. These large volumes of additional information that were previously unavailable provide manufacturers with more tools and information to grow and optimize their entire business.

Innovative Applications of RFID in Manufacturing

Here are some innovative RFID applications for the smart factory:

1. Digital Twin Technology: Creating a Real-Time Replica of Your Operations

A digital twin is a virtual model of a physical process, system, or product that mirrors real-world conditions using live streaming data. In manufacturing, digital twins are used to visualize production, simulate process changes, monitor asset health, and even test how new layouts or configurations might impact performance—before making real-world changes.

RFID in manufacturing plays a foundational role in powering digital twins. While IoT sensors provide raw data, such as temperature or vibration, RFID captures dynamic information about the location, status, movement, and identity of materials, equipment, and work-in-progress.

With RFID-tagged components moving across the production line, a digital twin receives continuous input on:

- Where each item is

- What stage it’s in

- Whether it’s idle, active, or delayed

- What machine or operator handled it last

Using a platform like MSM Solutions’ PortalTrack® RFID software, manufacturers can consolidate these real-time signals into a centralized system that feeds digital twin environments with accurate, up-to-the-second production data.

This real-time traceability provides teams with an up-to-date, visual view of what’s happening on the factory floor, even when they’re not physically present. They can:

- Identify bottlenecks as they form

- Simulate process improvements before implementation

- Predict equipment failures based on usage trends

- Test layout changes digitally

- Validate compliance in high-regulation environments (like medical device or automotive manufacturing)

By pairing RFID with simulation software, AI models, or business intelligence (BI) dashboards, manufacturers can build highly accurate, scenario-driven insights. This enables faster innovation, improved product quality, and fewer surprises in production.

At MSM Solutions, we help manufacturers implement RFID frameworks that support these advanced use cases, ensuring your digital twin strategy is built on a reliable foundation of real-time, actionable data.

2. Predictive Maintenance: Preventing Downtime Before It Starts

Unscheduled equipment failures can quickly become one of the most expensive disruptions in any manufacturing environment. Predictive maintenance uses data to anticipate failures and schedule repairs before issues escalate.

RFID contributes by tracking the location, status, and usage history of key assets—whether it’s a high-speed conveyor, a robotic arm, or a mold press. When RFID data is paired with IoT sensors or machine learning models, maintenance teams can:

- Identify wear patterns

- Flag overuse or misuse

- Schedule service at the optimal time

This reduces emergency repairs, extends equipment life, and keeps production lines running more reliably. RFID makes predictive maintenance more scalable and accurate, especially when integrated with your ERP or asset management systems.

3. End-to-End Supply Chain Visibility: Better Tracking, Fewer Bottlenecks

Today’s supply chains are more complex and interconnected than ever, and visibility is no longer optional—it’s essential. RFID gives manufacturers real-time insight into inventory, shipments, and product status at every stage of the chain, from raw materials to final delivery.

With RFID in manufacturing and logistics, companies can:

- Automatically track incoming materials and outgoing products

- Confirm order accuracy and shipment compliance

- Improve warehouse picking, staging, and replenishment

- Spot delays or bottlenecks before they disrupt production

- Meet just-in-time and just-in-sequence manufacturing demands

RFID also supports digital authentication to prevent counterfeiting and enables faster customs or compliance verification across borders.At MSM Solutions, we help manufacturers connect RFID data to their existing ERP and WMS systems through our PortalTrack® RFID software, enabling seamless, real-time visibility across the entire supply chain.

4. AI-Driven Process Optimization

AI is only as smart as the data it receives. RFID provides reliable, structured data by tracking how assets, materials, and products move across your facility.

By feeding RFID data into machine learning models or business intelligence tools, manufacturers can:

- Optimize machine utilization

- Identify root causes of inefficiencies

- Improve quality assurance

- Forecast more accurately

This supports leaner operations and better real-time decision-making.

5. Sustainability and Resource Efficiency

Sustainability is now a business imperative. RFID enables more sustainable manufacturing by enhancing the utilization, tracking, and recovery of materials and resources.

Manufacturers can use RFID to:

- Reduce overproduction and waste

- Monitor energy or material consumption by line or product

- Track recyclable components and manage reverse logistics

- Support environmental compliance with traceable reporting

It also enables smarter reuse or return programs by associating products with complete lifecycle data.

6. Hyper-Customization in Production

The demand for product personalization is growing. Whether it’s changing a label language, swapping packaging, or applying customer-specific configuration—RFID allows those changes to happen automatically.

Each RFID-tagged item can carry unique instructions that machines read at every stage of the production process. This supports:

- Flexible manufacturing

- Last-minute personalization

- Faster product switches without human input

It’s a powerful way to deliver customization at scale—without sacrificing speed.

7. Human + Machine Collaboration

As automation expands, so does the need for safe and synchronized workflows between machines and people.

RFID facilitates this by:

- Authenticating users and tools in real time

- Tracking worker location and access

- Ensuring only trained personnel interact with specific equipment

- Supporting safety protocols in hazardous environments

This level of traceability helps prevent accidents, improves compliance, and ensures teams are always using the right equipment the right way.

8. Post-Sale Engagement and Smart Product Experiences

RFID isn’t just a tool for manufacturing efficiency. It can also enhance the post-sale experience. By embedding RFID tags into products, brands enable customers to verify authenticity at the point of sale and access valuable information after purchase, such as:

- Warranty details

- Recommended accessories or spare parts

- Return instructions

- Recycling or disposal guidance

These “smart products” can even enable future reordering, loyalty rewards, or service alerts. With RFID, brands stay connected to the customer long after the item leaves the factory floor, extending the value of each interaction and paving the way for more personalized commerce.

RFID in Manufacturing: Applications and Impact

| Application Area | How RFID Enables It |

| Digital Twin Technology | Collects and manages live RFID data from tagged items across your operations. MSM’s PortalTrack® RFID software helps feed accurate, real-time data into digital twin environments for enhanced system visibility. |

| Predictive Maintenance | Tracks asset usage history to anticipate maintenance needs and reduce unplanned downtime when integrated with IoT and analytics tools. |

| Supply Chain Visibility | Provides end-to-end visibility of materials, WIP, and shipments. MSM’s PortalTrack® RFID software supports seamless integration with ERP and WMS systems. |

| AI-Driven Optimization | Feeds structured RFID data into machine learning models to uncover inefficiencies, predict outcomes, and improve resource planning. |

| Sustainability and Resource Efficiency | Monitors material usage and movement to reduce waste, enable recycling, and track environmental compliance across the lifecycle. |

| Hyper-Customization in Production | Supports item-level personalization through dynamic RFID tag data—enabling flexible production and last-minute configuration. |

| Human + Machine Collaboration | Authenticates equipment use, tracks personnel access, and enhances safety in automated environments. |

| Post-Sale Engagement | Enables smarter product experiences after purchase including warranty tracking, authenticity checks, returns, recycling, and future engagement. |

Why MSM Solutions Is Leading the Future of RFID in Manufacturing

At MSM Solutions, we know that every manufacturing operation is different. That’s why we take a tailored approach, working closely with your team to design, implement, and support RFID systems that align with your specific goals, compliance needs, and operational challenges.

Our PortalTrack® RFID software provides real-time visibility across your production environment, helping you streamline processes, ensure accuracy, and stay competitive in an evolving industry.

With a proven track record across sectors like automotive, healthcare, apparel, and logistics, MSM delivers trusted expertise and scalable results. We don’t just deliver technology. We provide long-term support, practical integration guidance, and solutions that are ready for what’s next.

Contact an MSM Solutions RFID expert today to see how we can help you implement RFID in manufacturing with confidence.