The demand for accurate, real-time asset tracking has never been higher. According to MarketsandMarkets, the global RFID market is projected to reach $5.24 billion in 2033, driven by the need for efficient tracking solutions in industries like manufacturing, healthcare, logistics, and retail.

RFID technology provides a scalable, automated solution for tracking physical assets in real time. From monitoring inventory levels in a warehouse to tracking hospital equipment across multiple locations, RFID systems ensure precise, efficient asset management throughout the entire supply chain.

In this comprehensive guide, we’ll explain how RFID Asset Tracking works, its benefits over traditional methods, and how you can implement it to streamline your business operations.

What is Asset Tracking?

Asset Tracking or Traceability is the process of monitoring and managing the movement, status, and location of physical assets throughout their lifecycle. This includes every stage, from acquiring raw materials to production, storage, distribution, and eventual disposal or recycling.

RFID asset tracking is a popular method used by companies to track and manage assets across locations with speed and accuracy. While RFID technology has a broad range of applications, one of its most common and valuable uses is asset tracking. By leveraging RFID tags and readers, businesses can quickly collect and access detailed asset information in real time, improving inventory accuracy, operational efficiency, and decision-making.

How does an RFID Asset Tracking System Work?

The RFID identification systems of products, merchandise, packages, etc., allows the manufacturer to give a unique ‘registration’ to each item, box, or pallet to initiate its traceability, establishing a system that allows us to recognize each piece individually and thus build their traceability along the chain. With the help of RFID asset management systems, tracking assets is a matter of linking an item to a location.

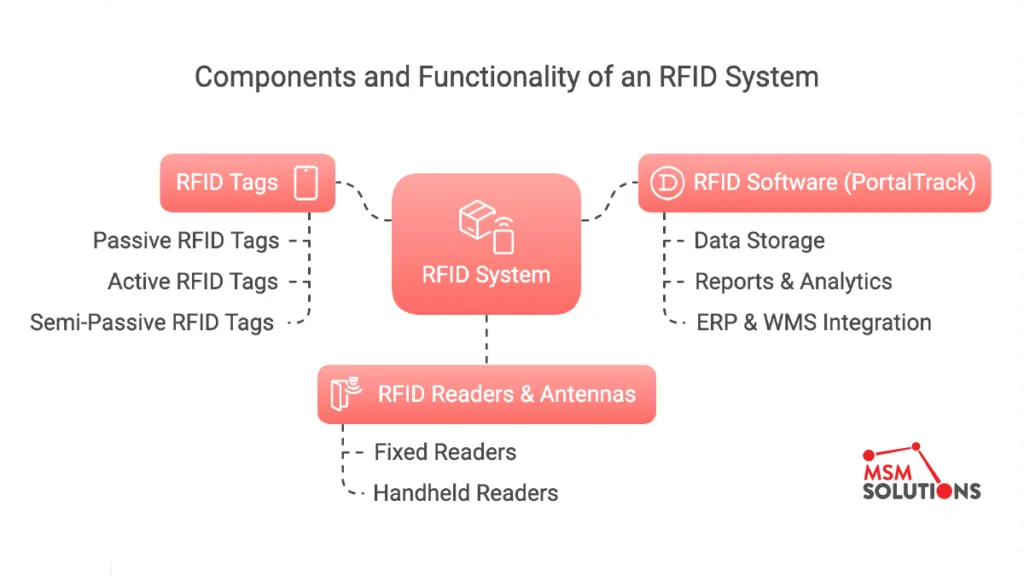

A fully integrated asset tracking solution tracks and monitors assets in real time. The RFID Asset Tracking System is powered by three key components:

- RFID Tags

- RFID Readers and Antennas

- Asset Tracking Software

Components of an RFID System

- RFID Tags:

- Small devices attached to assets that store unique data

- Types of Tags:

- Passive RFID Tags: Battery-free, activated by RFID readers, ideal for inventory management (Read range: up to 10 meters)

- Active RFID Tags: Battery-powered, capable of long-range tracking (Read range: up to 100 meters)

- Semi-Passive RFID Tags: Battery-assisted, offering improved read range and data accuracy

- RFID Readers & Antennas:

- Devices that capture signals from RFID tags and transmit data to the software

- No Line-of-Sight Required: Unlike barcodes, RFID readers can collect data without direct line-of-sight

- Types of RFID Readers:

- Fixed Readers: Installed at strategic points like entryways or production lines

- Handheld Readers: Portable devices used for audits and inventory counts

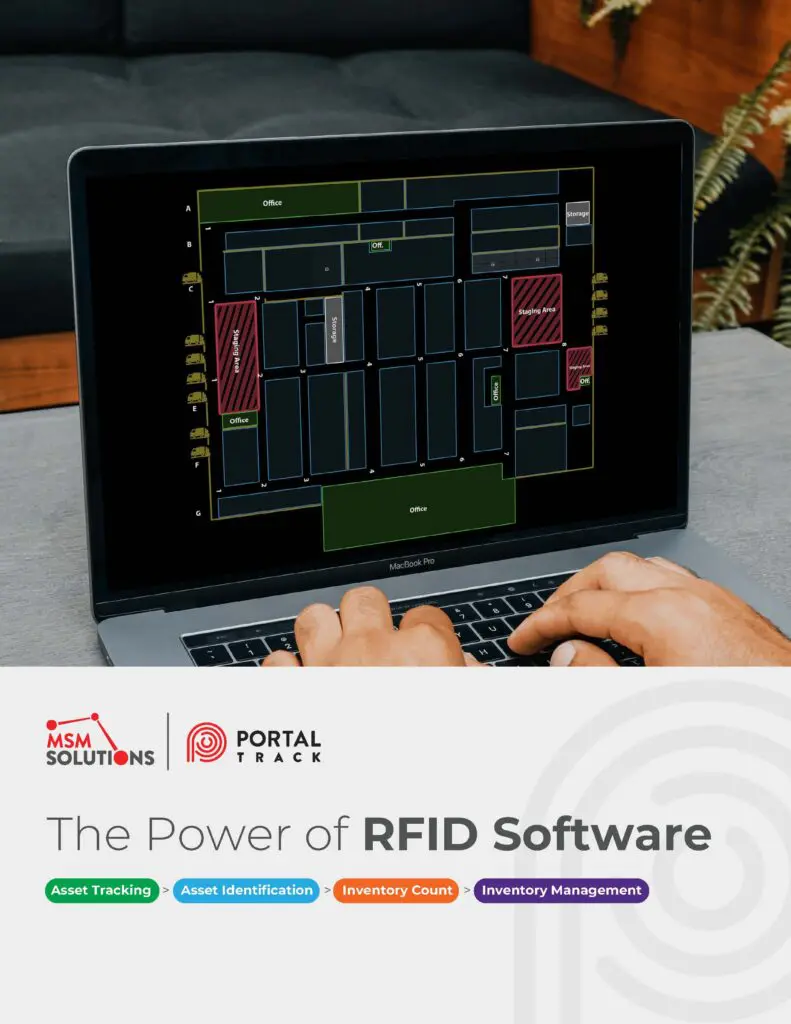

- RFID Software (PortalTrack):

- Centralized platform that processes data from RFID readers to provide real-time visibility

- MSM Solutions’ PortalTrack RFID Software offers robust integration with ERP and WMS systems for streamlined asset management.

- Features:

- Storing and organizing asset data

- Generating reports and analytics

- Providing dashboards accessible via web, mobile, or desktop interfaces

How Does an RFID Asset Tracking System Work?

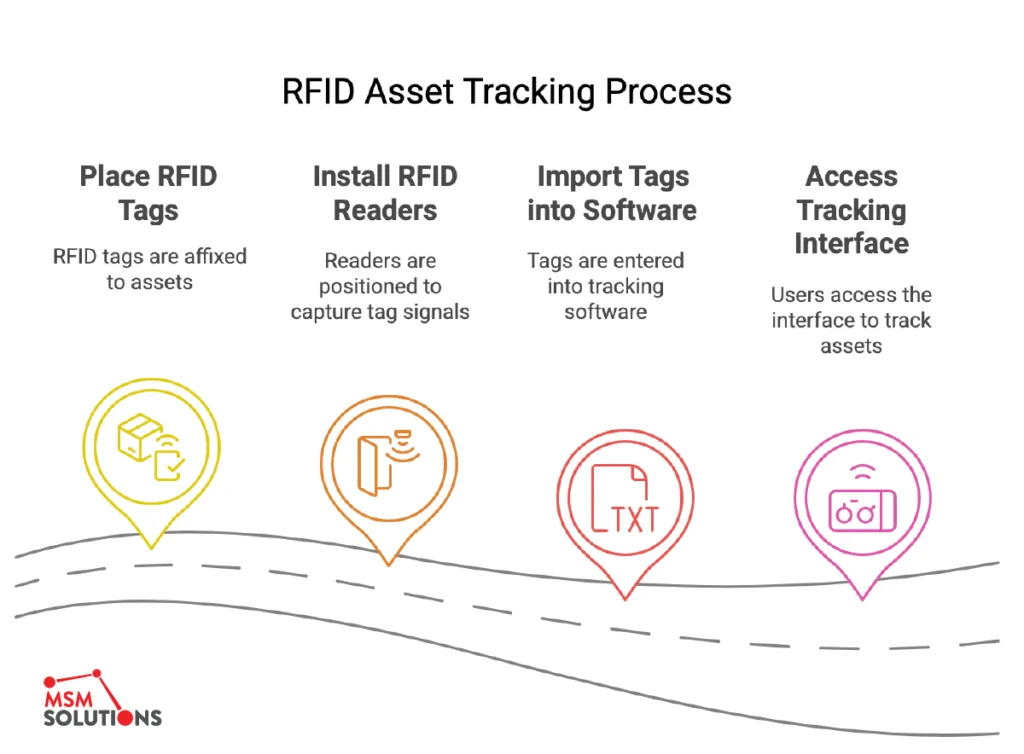

These three components work together to track assets globally or locally, and should be customized to meet the needs of any business environment. An Asset Tracking System lets you know exactly where your assets are in real time through the following process:

STEP 1: Place RFID Tags

RFID tags are physically placed on the item or assets, such as inventory items, containers, equipment, or pallets. These tags store unique data that identifies each asset and enables accurate tracking throughout its lifecycle

STEP 2: Install RFID Readers

The RFID readers are installed in strategic points so that they can “read” the signals emitted by the RFID tags. These readers can be fixed (stationary) or handheld (portable), depending on the application and environment.

STEP 3: Import Tags into Software

The data collected by RFID readers is imported into an RFID Asset Tracking Software like PortalTrack. This software processes the information, storing it in a centralized system for easy access and management.

STEP 4: Access Tracking Interface

Users can access the tracking interface via a laptop, web browser, or mobile device. The software provides real-time visibility into asset locations, movement history, and status, enabling better decision-making and efficiency.

What Are the Benefits of RFID Over Barcode When It Comes to Asset Tracking?

Barcodes have been a reliable and cost-effective method for asset tracking for many years. They are widely used in industries where direct line-of-sight scanning is practical and manual operations are sufficient. However, as businesses scale and require more sophisticated tracking capabilities, RFID technology offers several advantages over traditional barcode systems.

- Barcode relies on a human interaction to scan an item, while RFID tags allow automatic readings of items in motion without the need for physical touch or even eye contact.

- RFID can record simultaneous readings on an assembly or shipping line at distances up to 10 meters.

- RFID technology provides manufacturers with high-quality, reliable, product track-and-trace functionality throughout their supply chains.

- RFID platforms automate the product identification process during shipping, receiving, packing, and storage operations.

- Inventory counts are performed smoothly with fixed and mobile readers for greater visibility, efficiency, and safety.

- RFID systems can now not only follow the product throughout the supply chain but also learn about its interaction with the customer or consumer.

Comparing RFID and Barcodes

| Feature | Barcodes | RFID Technology |

| Scanning Method | Requires manual scanning | Automatic scanning (No line-of-sight required) |

| Read Range | A few inches to a few feet | Up to 100 meters (Active RFID) |

| Simultaneous Reading | Single item per scan | Multiple items read simultaneously |

| Durability | Prone to damage, requires clean surfaces | Durable, especially Passive RFID tags |

| Automation | Limited to manual processes | Fully automated, enabling real-time tracking |

| Cost Per Tag | Low | Varies (Passive RFID: low; Active RFID: higher) |

| Best Use Cases | Retail, Document Tracking | Inventory Management, Supply Chain, Manufacturing, Healthcare |

Today RFID technology offers strategic advantages to various industries like the manufacturing industry, since it can be used in the tracking of inventories more efficiently while providing visibility of real-time inventory traffic. Manufacturers need this real-time visibility for things like work in process (WIP), raw materials tracking, supply chain processes, inbound and outbound shipments, returnable racking, metrics and analytics, and process traceability.

Industries & Applications of RFID Asset Tracking

RFID Asset Tracking Systems are versatile and valuable across a wide range of industries. By providing real-time visibility, enhanced accuracy, and efficient data collection, RFID technology helps businesses streamline their operations and improve overall efficiency.

Key Industries & Use Cases

- Manufacturing:

- Monitor work-in-process (WIP), raw materials, and finished goods.

- Track assets throughout the production line for improved efficiency and quality control.

- Healthcare:

- Track critical medical devices, PPE, and hospital equipment across facilities.

- Improve patient care by ensuring the availability of essential assets and enhancing workflow efficiency.

- Logistics & Supply Chain:

- Enhance warehouse management, shipment tracking, and returnable asset monitoring.

- Improve supply chain visibility from production to final destination.

- Retail and Apparel:

- Achieve precise stock visibility, prevent theft, and optimize inventory management.

- Improve customer experience with better stock availability and faster fulfillment.

- Automotive:

- Track returnable and reusable packaging, including racks and crates.

- Monitor parts throughout the manufacturing process and supply chain.

- Enhance quality control, inventory accuracy, and production efficiency.

- Agriculture & Livestock:

- Track equipment, livestock, and produce to improve operational efficiency.

- Monitor environmental conditions and supply chain processes.

- Construction & Industrial Equipment:

- Track tools, machinery, and materials across job sites.

- Prevent loss, enhance maintenance tracking, and optimize resource allocation.

What To Look for in RFID Asset Tracking Systems?

RFID Asset Tracking Systems are increasingly gaining more popularity in the manufacturing industry. The technology has many benefits in the manufacturing industry, including:

- Tracking of items, containers, and pallets from production to supplier and final destination in real time

- Returnable and reusable rack tracking.Supplier sends parts to the manufacturer in returnable, reusable crates. These crates are tracked in real time to ensure they are returned from manufacturer to supplier.

- Record keeping of the journey products

- Detection of errors and problems

- Notifications and alerts in real time if articles leave the warehouse without authorization

- Control of the location of products within the warehouse

- Visibility of work in process and traceability of production workflow in real time

- Validation and verification that right parts and right counts are being used in the manufacturing process and right products are being shipped, and

- Quality control tracking

The product’s path, from production to retail, provides valuable information in times of Big Data. As a result of this newly available information and with the help of business intelligence or data mining applications, manufacturers can now handle alternative and variable solutions for just-in-time and just-in-sequence production processes. With RFID, today, manufacturers can obtain and utilize deeper knowledge of production control, process optimization, and quality control.

Want to dive deeper?

Explore our step-by-step resources on:

🔹 RFID Asset Identification

🔹 RFID Asset Management

Conclusion

Implementing an RFID Asset Tracking System can transform the way your business manages assets, inventory, and operational efficiency. With real-time visibility, improved accuracy, and automated data collection, RFID technology offers a powerful solution for industries ranging from manufacturing and healthcare to logistics and retail. At MSM Solutions, our PortalTrack RFID Software provides what you need to enhance your asset-tracking capabilities and gain complete control over your operations.

Or contact our RFID experts to learn more about how we can help you implement the right RFID Asset Tracking Solution for your business.