The true purpose of any manufacturer is to create quality products cost-efficiently so the return on investment is as high as possible. By using RFID software to track your work-in-progress (WIP) manufacturing, you can ensure your WIP processes are streamlined and transparent.

What is a WIP in Manufacturing?

In the manufacturing industry, a work in progress (WIP) is a product that has not been completed for public distribution or sale. It’s a partially finished product that still requires labor and time to complete.

To know where you stand in the manufacturing process, you need to know particular specifics about your WIPs that affect your production and delivery schedules:

- Components and materials in stock

- Components and materials consumed for every finished product

- Completed products in stock

- The number of products you can manufacture with the components you have in stock

However, inefficient processes can inflate overhead costs resulting in expensive manufacturing WIPs. There are five key areas where inefficient WIP manufacturing processes can result in higher costs and low ROI.

- Inventory & Materials Management

- Quality Assurance

- Inbound and Outbound Shipment Verification

- Process Traceability (Asset Tracking)

- Real-Time Manufacturing Error Prevention Alerts

Using RFID technology, you can address these issues to minimize costs while improving your processes and manufacturing times.

Inventory & Materials Management

Before manufacturing, your products consist of smaller components – bits and pieces waiting to be assembled. Until then, they’re spread across your facility, taking up space and sometimes getting lost in the process. Plus, you don’t always know what you have in-house. This can cause delays if you run out of components and are unable to complete production of your WIPs.

RFID tags make it easy to perform inventory management – determining component counts and locations in real-time so you can improve your WIP processes and lower overhead costs. By using zone tracking, you can perform real-time management of your components and materials so you know inventory counts and locations.

Quality Assurance

While some components and materials are seemingly evergreen, most have a shelf life that affects the quality and performance of the products you manufacture. To manufacture the best version of your product, you need quality assurance for your components to meet customer expectations.

RFID software can track your critical dates so you always know when you purchased and received your raw materials. Then you can also establish alerts to warn you when specific components are nearing their ‘use by’ dates. Plus, you can ensure that the right components are in the right place at the right time.

Inbound and Outbound Shipment Verification

In the best of times, supply chains can be hectic, chaotic messes. And we haven’t exactly been living in the best of times. It isn’t easy to plan production schedules when you don’t know when (or even if) you’ll be getting the components and materials you need for your WIPs.

With RFID readers, you gain better insight into your supply chain so you know where your WIP components are as they travel from their place of origin to your manufacturing facility. This helps you forecast production schedules and allows you to inform your customers of potential delivery dates.

Process Traceability (Asset Tracking)

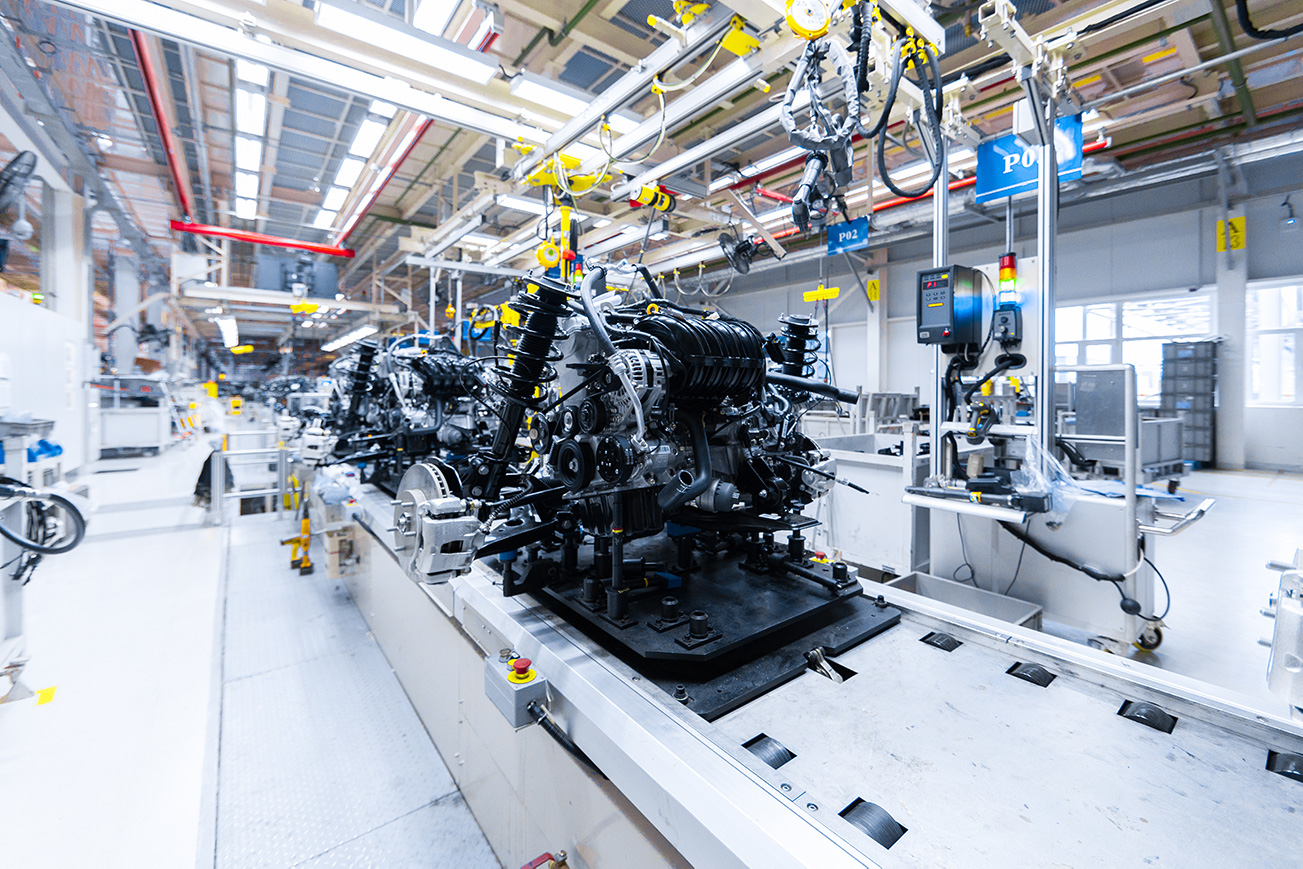

Manufacturing requires specific step-by-step processes that occur along an assembly line. The last thing you want is your product to skip steps or work out of order. That could quickly lead to damaged or nonfunctioning products.

RFID technology can help you track your WIPs along the assembly line to ensure your manufacturing process is followed step-by-step. This asset tracking allows you to track your WIPs through manufacturing to determine timelines for product availability and inventory counts.

Real-Time Manufacturing Error Prevention Alerts

No one likes product delays but no matter what you do to prevent them, delays still happen. Assembly machines aren’t always perfect. They break down or get misaligned, resulting in manufacturing errors.

Using RFID technology, you can get real-time alerts when manufacturing processes break down. This helps you minimize downtime, prevent revenue losses and helps you save WIPs that could have been damaged if your off-kilter manufacturing process had gone unchecked.

How MSM Solutions Can Help Your WIP Processes

MSM Solutions uses RFID technology and software to solve manufacturing WIP challenges.

Track and manage your WIP manufacturing processes through PortalTrack, MSM Solution’s customizable software solution. Through an innovative approach to manufacturing, you’ll be able to identify, track, count, and manage your WIPs, components and finished products accurately and efficiently.

With intuitive integration across mobile, desktop and web-based platforms, you can easily manage and optimize your WIP processes to improve your manufacturing processes in various manufacturing industries like automotive, retail and healthcare.

Contact us today to learn more about how MSM Solutions can help you improve your WIP manufacturing processes so your product delivery is more efficient, dependable and profitable.