RFID Solutions

Manual processes, inventory inaccuracies, and limited visibility create costly inefficiencies across your operations. Since 1981, MSM Solutions has delivered RFID solutions built to solve these challenges — backed by deep industry expertise and partnerships with the world’s leading RFID technology providers.

What is Radio Frequency Identification (RFID)?

Radio Frequency Identification (RFID) is a wireless technology that allows businesses to identify, track, count and manage just about anything in real time without human interaction. The benefits of RFID solutions are proven and MSM Solutions has over four decades of experience designing, integrating and managing cutting-edge RFID systems for some of the largest and most recognizable brands on the planet in the retail apparel, healthcare and manufacturing industries. By partnering with the world’s leading RFID hardware companies and utilizing its own proprietary PortalTrack software, MSM Solutions is able to help companies take complete control of their businesses from source to sale. Such partnerships further solidify MSM Solutions’ position as one of the most reliable RFID solution providers available.

Key Components of an RFID Solution

A complete RFID solution includes the right combination of hardware and software to support your business goals. MSM Solutions offers a full range of RFID components, from readers, antennas, and tags to our proprietary PortalTrack software designed to deliver reliable performance in demanding environments. Whether tracking assets, managing inventory, or automating workflows, our RFID technologies provide the flexibility and scalability to fit your operational needs.

Fixed RFID Readers

With access to the world’s leading portfolio of RFID technologies, MSM Solutions has installed a large number of Fixed RFID Readers across a diverse range of challenging applications.

Whether it’s fixed to a conveyor belt or near loading dock doors, Fixed RFID readers are built to work in a variety of environments, deliver extremely high-performance read capabilities and can easily support long read range applications with ease.

Handheld RFID Readers

MSM Solutions has helped numerous businesses enable their mobile workforce through the use of mobile and Handheld RFID readers.

Whether it’s tracking items and assets in the field, managing inventory on the retail floor or tracking receivables at the distribution center, today’s handheld RFID readers combine the performance of fixed reader technology with the flexibility, ease of use and connectivity found in many of today’s consumer mobile devices.

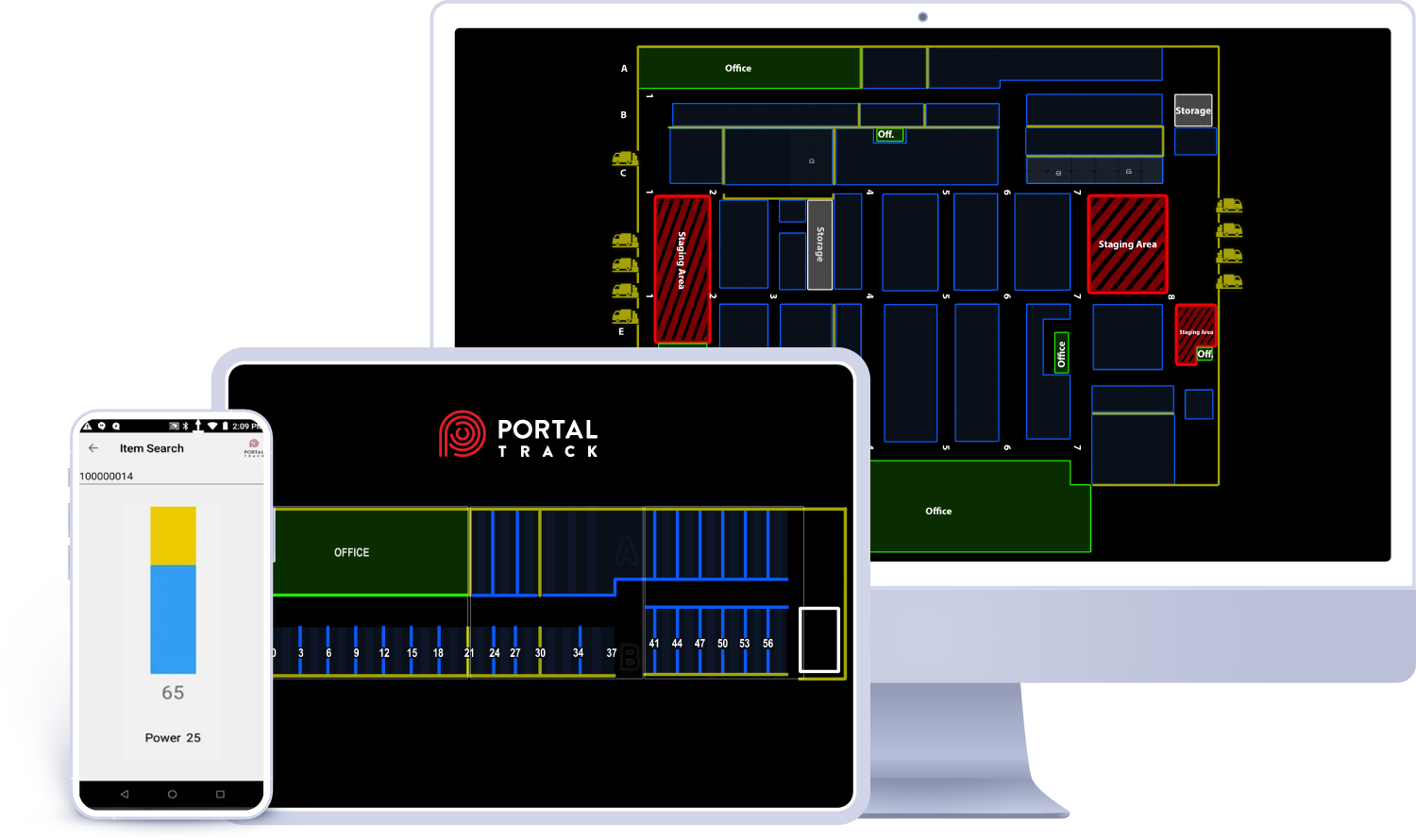

PortalTrack RFID Software

At the core of any RFID application or system is the software that powers it. And with MSM Solutions’ PortalTrack software, the possibilities are endless. Deployed globally and trusted by many of the world’s largest organizations, PortalTrack gives you the freedom to tailor your RFID and barcode data collection applications for real-time monitoring and analytical reporting of your business activity. With PortalTrack, you make the rules; we don’t.

RFID Antennas

RFID antennas are essential to every RFID system, transmitting signals between readers and tags to ensure accurate data capture. MSM Solutions provides high-performance antennas designed for various applications, including wide-area coverage, near-field reads, and challenging industrial environments — configured to optimize your RFID solution’s performance.

RFID Tags and Labels

RFID tags and labels come in a wide variety of form factors, including apparel hangtags, paper shipping labels, hard encased tags and specialty tags for tracking on-metal and liquid-based items. MSM Solutions can print and encode RFID tags and labels that are tailored specifically to your solution or application. Just like traditional non-RFID labels, MSM can print linear and 2D barcodes as well as human readable number sequencing, product descriptions and brand identities.

Applications of RFID Solutions

MSM Solutions has helped thousands of companies worldwide implement RFID solutions and barcode systems that improve operational efficiency and solve complex business challenges. From manufacturing and retail to healthcare, logistics, and automotive, our RFID applications are tailored to meet the needs of your industry. Whether you’re managing inventory, protecting your brand, or automating your shipping and receiving processes, MSM delivers proven solutions designed to scale with your operations.

EPC Printing and Encoding

As pioneers in multi-chip vendor Electronic Product Code (EPC) serialization, MSM’s PortalTrack EPC printing and encoding solutions have been deployed globally by some of world’s largest and most recognizable brand owners. Trusted and proven, PortalTrack and the RFID experts at MSM enable

Zone and Item Level Tracking

Whether it’s in the back of your warehouse, on a shelf in a laboratory or on a pallet in a regional distribution center, PortalTrack and the RFID experts at MSM enable businesses to track, locate and manage their items and assets in real time. As a result, businesses no longer have to ask themselves where are my “things” because they’ll always know thanks to real-time item visibility and real-time intelligent analytical reporting.

Powered by RFID technology, this level of business intelligence can reduce the time it takes to locate an item by as much as 90%, enabling businesses to operate more nimbly, fulfill orders faster and increase their capacity potential. Using fixed RFID readers positioned at strategic chokepoints and mobile RFID readers on the floor, PortalTrack gives businesses the power to locate items in real time regardless of where their physical location is.

Brand Protection

Every year, major retailers and brand owners from every corner of the world experience the pains related to either having their merchandise stolen and then sold in grey markets, or having their products counterfeited and sold as genuine, and in many cases both. Thanks to PortalTrack from MSM Solutions and RFID technology, businesses can create a digital DNA for their items and now safeguard themselves from these multi-billion-dollar issues that have plagued the retail industry for years.

Brand owners can effectively protect the value of their brands by ensuring product authenticity at all touchpoints throughout the entire supply chain, from point-of-origin to point-of-sale. By verifying and validating their Electronic Product Code (EPC) data with PortalTrack, retailers can ensure that genuine merchandise is being sold in the proper channels, quickly identify counterfeit goods, and more effectively deal with stolen goods. We encourage you to view The Benefits of Validating RFID EPC Tag Data video to learn more about how EPC verification and validation can help your business combat these challenges.

RFID Software Application and Integration

With decades of experience in RFID and barcode data collection systems, MSM Solutions’ in-house engineering team has the software and hardware expertise to bring efficiency and accuracy to all of your unique business processes. Whether you’re wanting to deploy a standalone or cloud-based system, connect to a PLC interface, or integrate with a WMS or ERP system, MSM can implement RFID solutions using its PortalTrack software into your existing business operations without causing any interruptions.

With its scalable platform and superior hardware integration capability, PortalTrack provides endless customized application possibilities. So whether you want to gain real-time visibility for key manufacturing metrics via web-based dashboards or monitor inventory levels throughout your entire global retail operations, the software application and integration experts at MSM can assist you with every aspect of your application.

Inventory Management

In today’s ultra-competitive global business environment, conventional methods of tracking inventory and locating items, such as manual data entry and human-assisted scanning are extremely inefficient and costly to perform. When on-hand inventory counts and item locations are delayed, sales are lost, product is wasted and labor costs increase.

Utilizing its PortalTrack software solution and the latest in RFID technologies, MSM Solutions inventory management experts canimprove inventory accuracy and reduce cycle count inventories by over 75% on average. By delivering real-time visibility capabilities, PortalTrack enables businesses to better manage their inventory by providing them with the ability to monitor raw materials, finished goods and critical assets in real-time throughout their entire operations. Contact MSM Solutions today to learn more about how PortalTrack can enhance your inventory management.

Automatic Print and Apply

High-speed in-line label and barcode printing is one of the most efficient ways to increase accuracy and reduce labor costs. The automatic print and apply label and barcode printer systems that MSM delivers to its customers are designed to run 24/7 and can be integrated with existing PLC controls, in-line barcode scanners, or fixed RFID readers.

At the core of any tracking and identification system is the label application system and media that deliver the barcode, graphic or any other unique visual identifier for a particular item or groups of items. From basic shipping to graphic-rich and environmentally-demanding labels, MSM Solutions has been deploying and maintaining high-speed labeling and encoding systems for some of the world’s most trusted brands for over two decades.

Shipping and Receiving

Two of the most critical components of any operation are its shipping and receiving processes. Whether receiving items for downstream production or shipping finished goods to distributors and customers, errors in these operational areas can have serious effects that can result in delayed production, additional labor costs and products not leaving on time. With RFID technology, you can be confident that the right products get shipped to and received at the correct destination every time.

For decades, MSM Solutions has been at the forefront of helping businesses embrace automation technology and adapt their shipping and receiving processes through the use of RFID solutions, barcode, printing and mobile technologies to improve their efficiency and maintain maximum productivity.

Work in Process

What is a WIP in Manufacturing?

In the manufacturing industry, a work in progress (WIP) is a product that has not been completed for public distribution or sale. It’s a partially finished product that still requires labor and time.

The true purpose of any manufacturer is to create quality products cost-efficiently so the return on investment is as high as possible. By using RFID software to track your manufacturing work-in-progress (WIP), you can ensure your WIP processes are streamlined and transparent.

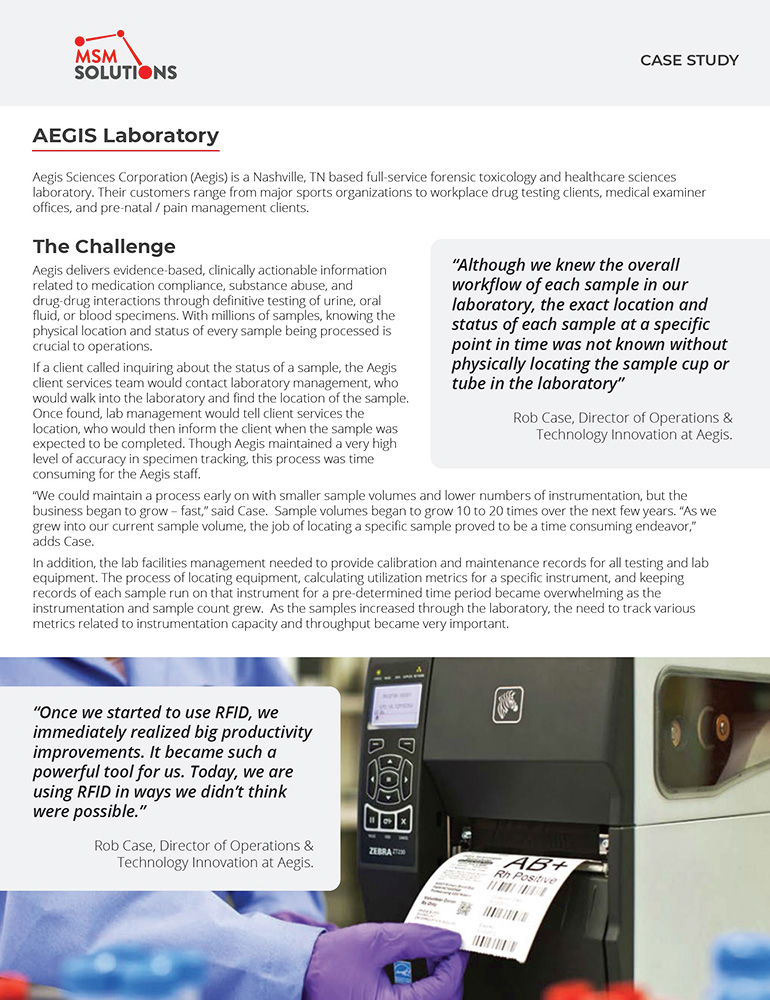

RFID Solutions Case Studies

See how MSM Solutions delivers results with real-world RFID solutions across industries, including retail and apparel, manufacturing, healthcare, distribution logistics, and automotive. From improving inventory accuracy to streamlining production and protecting brand integrity, these case studies highlight how our customers are solving complex challenges and driving measurable success with MSM Solutions’ RFID technology.

Benefits of RFID Solutions

Businesses across industries are turning to RFID solutions to address common operational challenges. By automating data capture and enabling real-time insight, RFID delivers measurable benefits that improve performance, reduce costs, and support smarter decision-making across your organization.

Real-time inventory visibility

RFID systems provide up-to-date tracking of inventory and assets across locations—reducing stockouts, overages, and manual checks.

Improved accuracy

RFID automatically identifies multiple items without a direct line of sight, reducing human error in inventory, shipping, and receiving.

Greater efficiency

RFID solutions streamline everyday operations by automating tasks like scanning, counting, and item verification—saving time and labor.

Stronger asset management

Track the location, movement, and condition of critical assets in real time, improving traceability and reducing loss or theft.

Lower operational costs

With fewer manual processes and better data, businesses reduce labor hours, improve workflows, and make faster decisions.

Scalable integration

RFID can be easily integrated into your existing systems and workflows, whether you’re managing a single facility or a global supply chain.