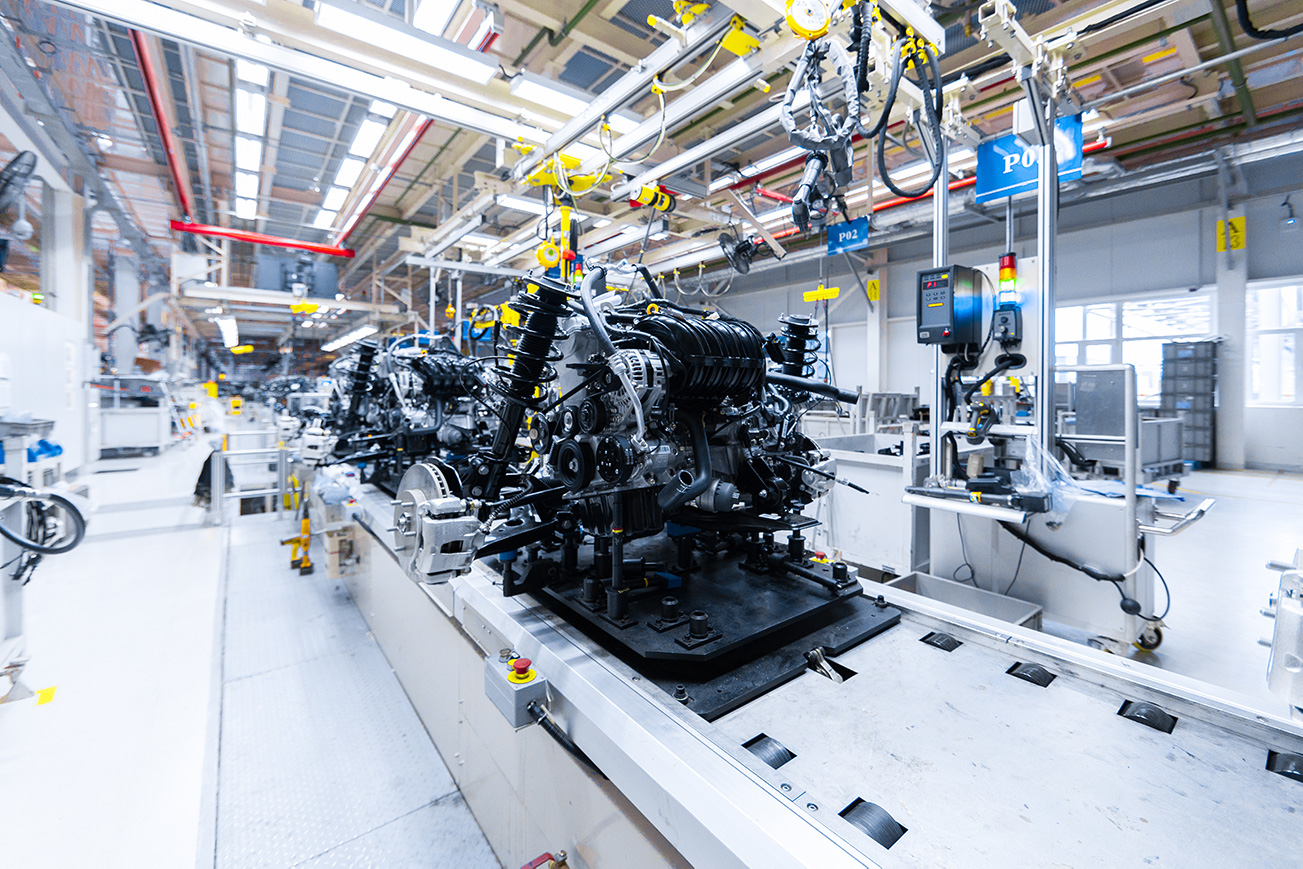

Manufacturing Software

Complete control of your materials and assets from start to finish

Barcode and RFID Software for Manufacturers

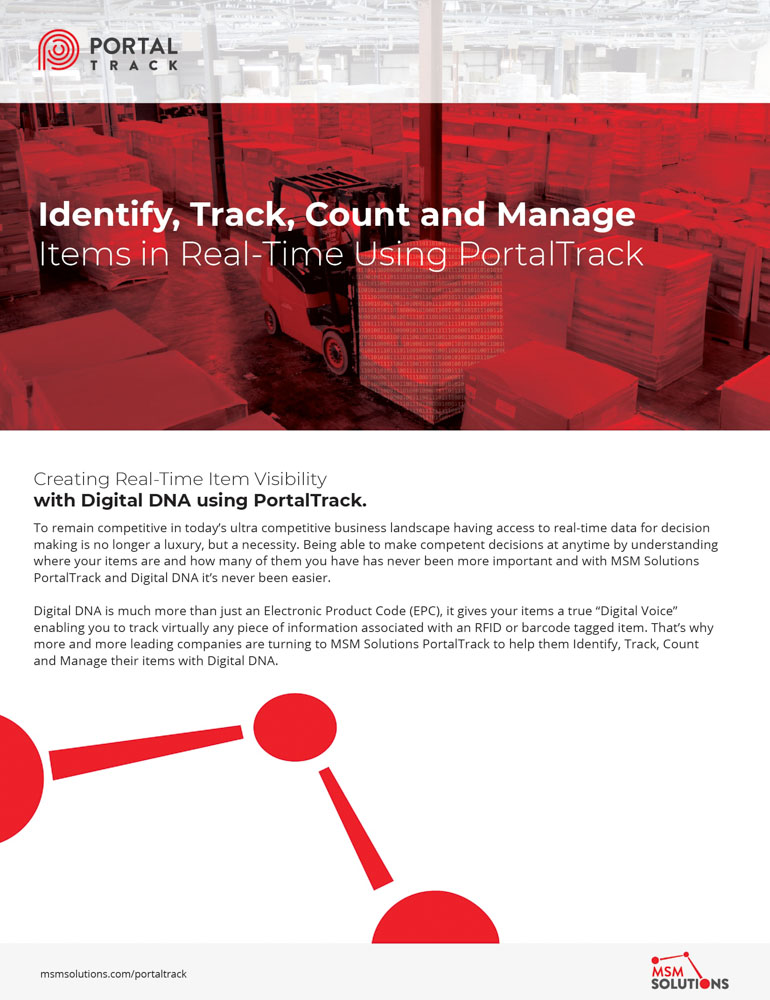

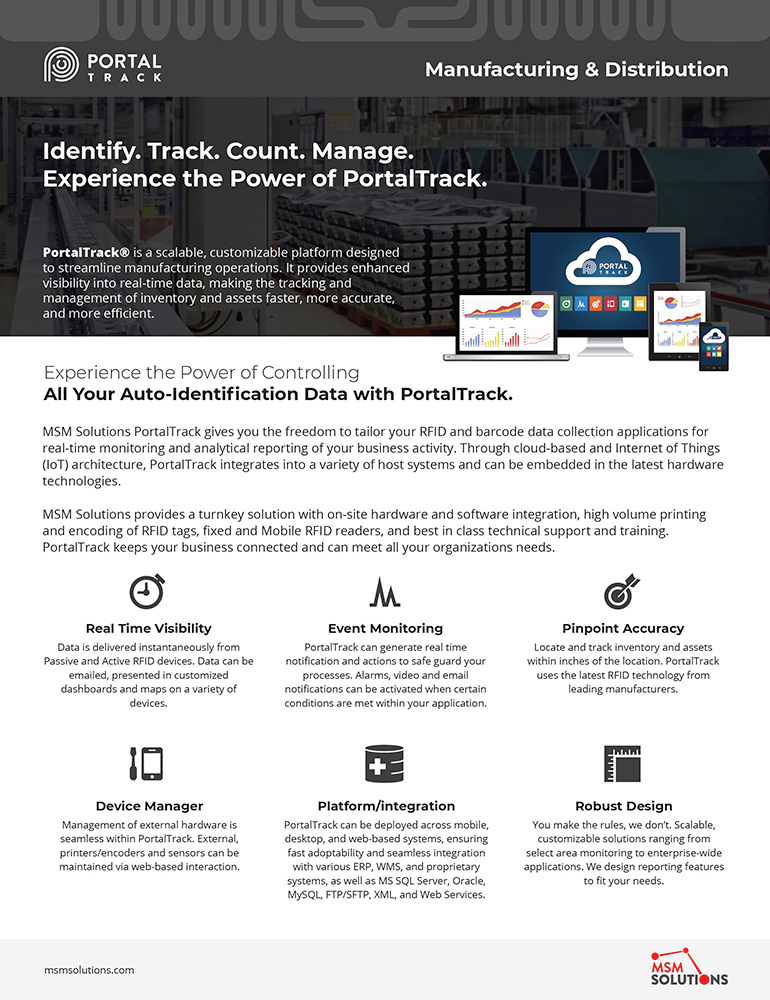

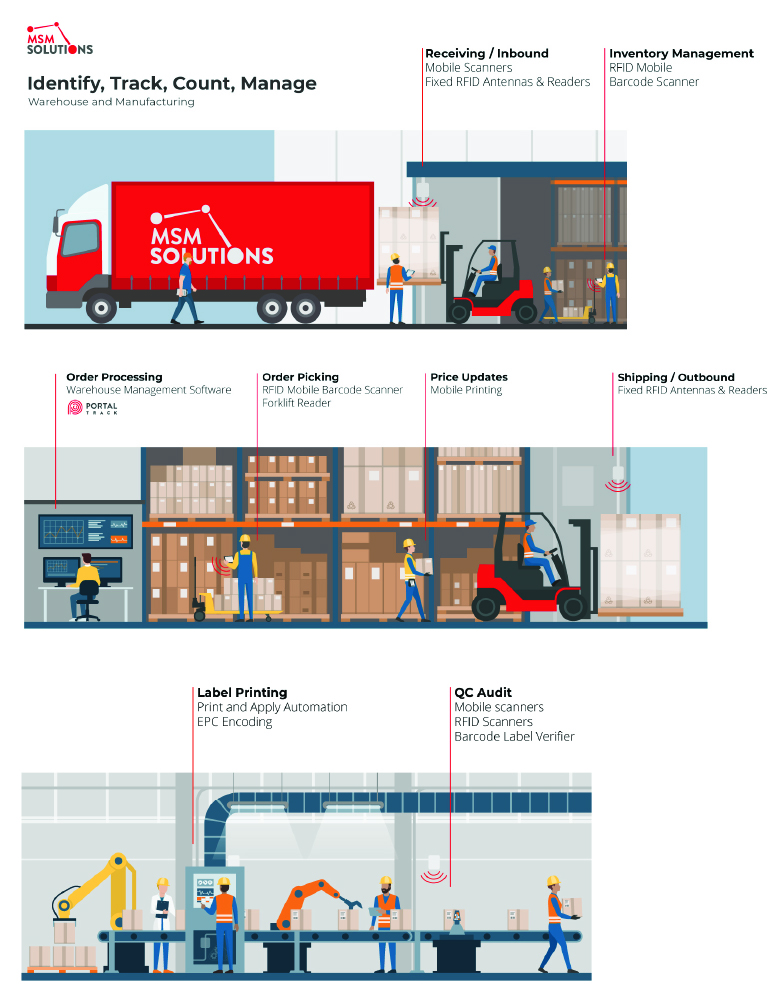

Deploying RFID technology is a challenge. However, the increased speed, inventory accuracy and visibility that RFID brings to the entire manufacturing process is part of the Internet of Things (IoT). MSM Solutions’ PortalTrack® makes it easy for you to integrate IoT across a variety of manufacturing processes and utilize existing data collection technologies like barcode together with RFID.

With PortalTrack, you make the rules — we don’t.

Why PortalTrack for Manufacturing

In the manufacturing process, RFID and barcode technologies are powerful IoT tools that enable improved production times, increased inventory accuracy, error reduction, better routing information, round-the-clock asset management, and other key operating efficiencies. MSM’s PortalTrack Manufacturing software provides customers worldwide the ability to deploy and integrate a scalable, real-time IoT visibility solution to access data and make decisions instantaneously based on the information received from barcode and RFID installations.

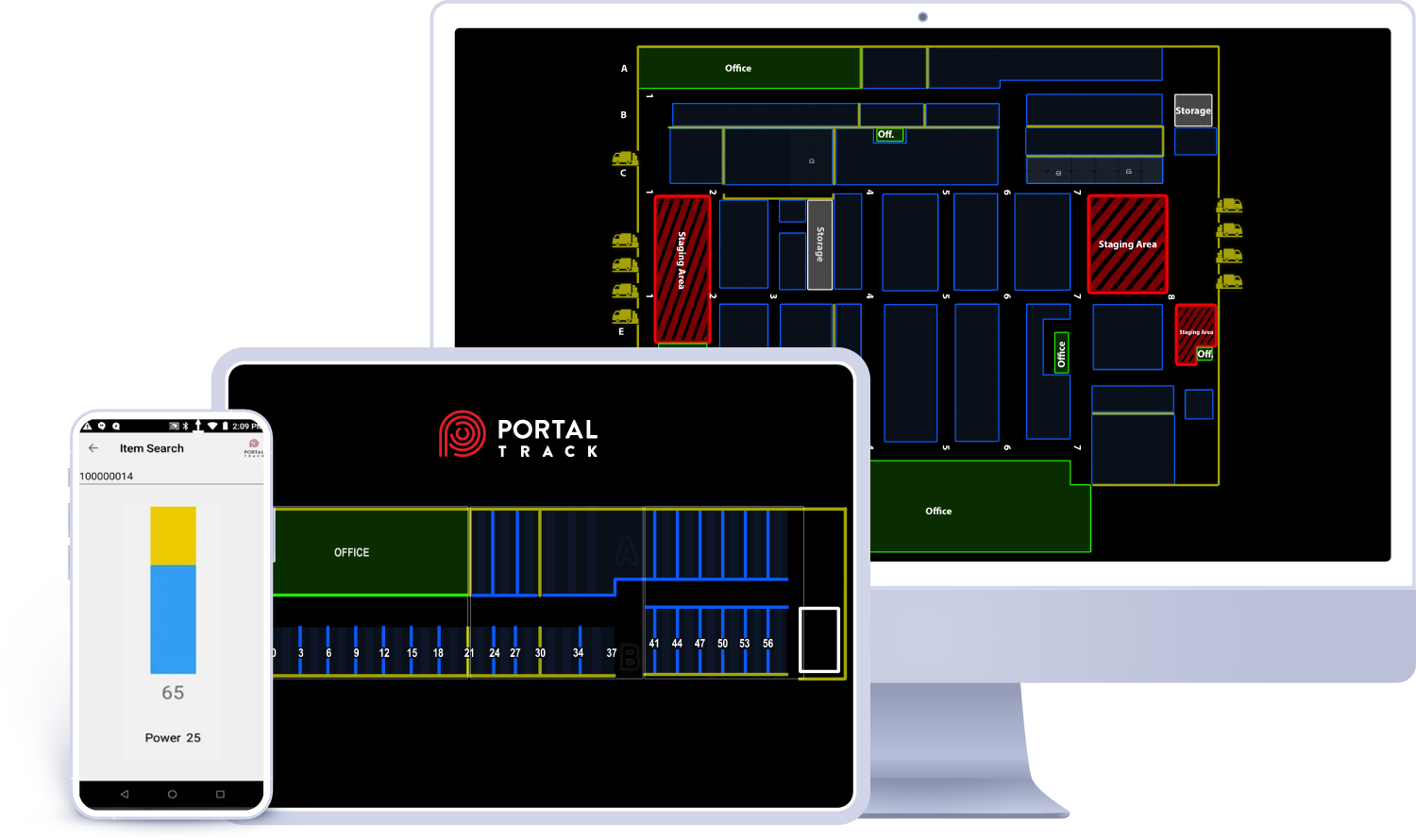

PortalTrack can be implemented in remote manufacturing plants and easily managed with its cloud-based architecture. Real-time information can be delivered on a variety of platforms including Windows, Windows Mobile, iOS and Android. Drive critical business decisions with web-based dashboards, facility mapping and email alerts, which provide instant access to the manufacturing process.

Key assets and critical equipment can be continuously managed by utilizing PortalTrack’s customized integration into your business environment. Capture data on a wide range of signal inputs noting exact locations, time stamps, product flow and information like environmental factors and employee interaction. Whether you’re gathering reads from unattended RFID readers or performing inventory on mobile devices, PortalTrack will allow you to spend less effort counting and tracking while increasing accuracy.

Popular Use Cases for PortalTrack Software for Manufacturing

Inventory Control

Track Work in Progress (WIP)

Quality Assurance

Process Traceability

Asset Tracking

Real-Time Error Prevention Alerts

EPC Encoding

Anti-Counterfeiting

Reduce Shrinkage

Core Benefits of PortalTrack Software for Manufacturing

Reduces

Operational Costs

Automated processes and real-time inventory management significantly reduces labor and error costs associated with manual processes.

Increase Supply

Chain Efficiency

Real-time industrial internet of things (IIOT) visibility into all aspects of operations from source to shelf with comprehensive reporting and performance.

Best Total Cost

of Ownership

PortalTrack is a scalable solution with a tailored cost structure that can start with a single application and extend into a global enterprise solution and beyond. MSM Solutions provides the RFID tags, barcode labels, RFID readers, mobile technology, and printers to fulfill the entire solution at the best cost.

Backed by

MSM Solutions Support

Complete turn-key support, integration and installation with best in class technical support on the lifetime of the product.

PortalTrack Manufacturing Quick Resources & Documents

Explore MSM’s PortalTrack Manufacturing solution even more and get up to speed quickly on the value that RFID and EPC technology can deliver your business.

Top Five Technical Features of PortalTrack

Proven ERP, WMS & Proprietary Integration

Deploy in the cloud or on-site, integrates with the world’s leading ERP and WMS systems such as Oracle, SAP, SQL and Web Services.

Pioneer in Multi Chip Vendor EPC Serialization

PortalTrack supports both MCS and manage serialization of EPC data from the world’s leading RFID tag manufacturers such as Impinj and Alien.

Runs Anywhere on Any Device

Through its cloud-based architecture, PortalTrack can be accessed from anywhere using a web browser, Windows, Windows Mobile, iOS or Android device.

Flexible and Customizable Application Development

A scalable platform that is highly customizable to fit your unique business processes.

Seamless External Hardware Management